Color steel tile roof photovoltaic power station installation solution

Color steel tile roof photovoltaic power station installation solution

With the rapid development of distributed photovoltaics in China, the roof is the most important carrier for installing photovoltaic power stations. The biggest advantage for ordinary people is that they can use building roofs to build photovoltaic power stations, and the construction period is short. But there is a big disadvantage that the power generation is closely related to climatic conditions and the roof application environment. So what kind of color steel tile roof is suitable for photovoltaic installation? As a world-leading manufacturer of solar photovoltaic brackets, Starwin Solar has summarized the following factors to be considered and practical application solutions based on years of practical experience in production!

First, we need to consider several factors:

1. Whether the service life of the colored steel tile on the colored steel tile roof can reach the minimum life required by the photovoltaic power station.

2. Whether the roof load can meet the specification requirements of distributed photovoltaic power stations.

3. The waterproof requirements of the roof after photovoltaic installation.

4. For the different roof orientations, the design of the photovoltaic support system matrix.

The solutions summarized by Starwin Solar are as follows:

1. Color steel tiles generally need to be replaced every 10-15 years. Therefore, color steel tiles with a long service life need to be replaced in consultation with the owner.

2. The roof requires load bearing capacity: 0.15KN/㎡ when the modules are fully paved. Factory buildings that do not meet this indicator need to be reinforced.

3. If the owner has high waterproof requirements for the roof, or the roof is relatively old, it is necessary to do waterproof and anticorrosive treatment on the roof before installation.

4. When the roof is not facing the sun, the support matrix needs to be designed properly to ensure high power generation.

For the situation where the color steel tile roof does not face the sun, the starwin color steel tile inclined bracket is such a photovoltaic support system designed for color steel tile roofs with different orientations. The biggest advantage of this bracket is that it can solve the different roof orientations without destroying the roof self-waterproof system. The front and rear feet of the system are used to achieve the best sunlight angle. According to customer needs, the solar panel can be flat or higher than the roof. In this way, although the roof does not face south, under the action of the support system, the power station matrix can be made to face south, so as to obtain sufficient sunshine, so as to realize the maximum benefit of power generation.

Starwin Solar has a comprehensive R&D team integrating sheet metal design, structural design, and civil engineering, and can propose the most practical and cost-effective solution according to actual construction requirements.

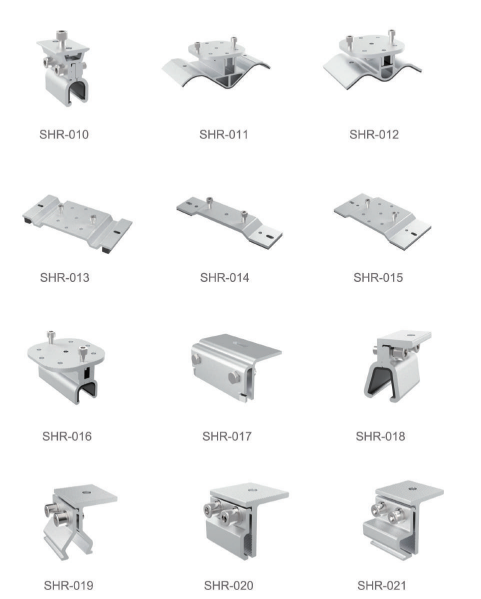

The inclined photovoltaic bracket system uses different types of color steel tile fixtures and unique connection design of the roof, which makes installation convenient and quick; and different color steel tile roof structures correspond to different fixtures. The better the fixture and the color steel tile match, the stronger the bracket installation. From this point, it also reflects the flexibility and versatility of the tilt bracket.

Tips for operation and maintenance of photovoltaic power plants:

1. Daily maintenance: usually pay attention to carefully inspect the power station to observe whether the module glass is damaged; whether there is any sharp object contacting the surface of the module; whether the module is blocked by obstacles or foreign objects; whether there is corrosion near the grid line of the battery (such corrosion The situation is caused by the damage of the packaging material on the surface of the module during installation or transportation, which causes water vapor to penetrate into the inside of the module); observe whether the backplane of the module has burn-through traces; check whether the fixing screws between the module and the photovoltaic bracket are loose Or damaged, and make timely adjustments or repairs.

2. Preventive maintenance: pay attention to regular inspection of the connector, cable, and junction box sealant to ensure that there are no cracks or cracks in the photovoltaic module for signs of aging.