How single-axis tracking can improve the power generation efficiency of solar power plants

Obtaining better energy harvest and maximizing return on investment are the primary goals for utility-scale solar plant owners and developers.

Today, focus is shifting to solar trackers–motorized structures that orient photovoltaic panels toward the sun in order to collect more direct sunlight throughout the day–as a reliable means to achieve these objectives. According to a recent research report by analyst firm IHS, single-axis trackers will be the preferred type of balance of system ground-mounted structure for PV modules in the USA this year. Indeed, single-axis trackers increase plant production up to 25% in comparison to fixed-tilt installations.

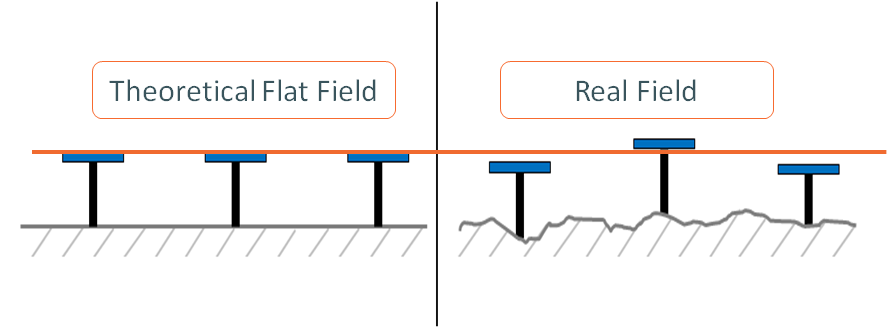

The energy output of a solar plant equipped with single-axis trackers can be further optimized by implementing an efficient tracking process. Basic yield calculations consider a perfectly flat terrain. However no field is completely flat. Slopes and terrain irregularities generate production losses that should be correctly anticipated. Solar tracking expert took into account those variations in the terrain and developed SMARTracking, an intelligent patented two-step tracking process to address the impact of non flat fields and generate up to 5% additional yield annually, compared to other basic solutions. Let’s take a look at how it works.

Step 1: Offsetting land irregularities during the design study phase

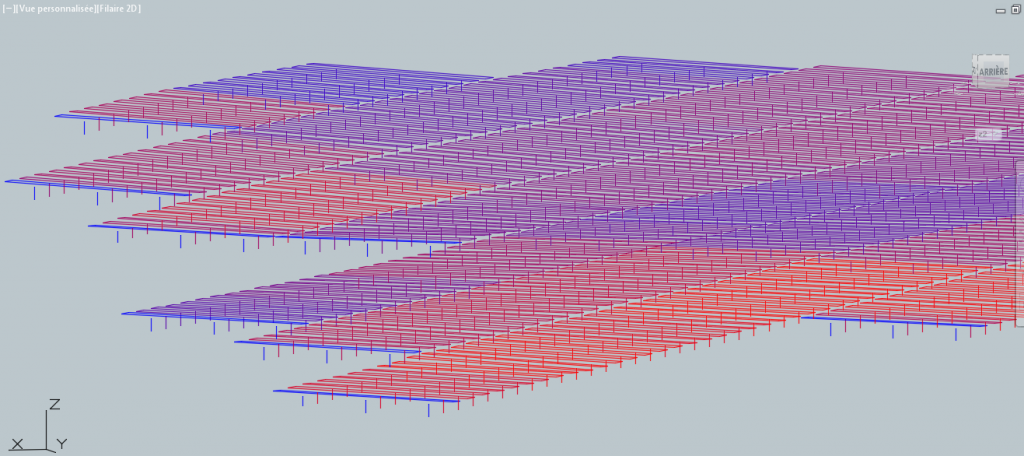

The first step of this process consists of a three-dimensional optimization of the plant layout at the design study phase of the project. Prior to carrying out a 3D study of the plant, a 2D plant layout is created and optimized according to the shape of the plant’s site borders.

The 3D optimization starts with a detailed topographic analysis of the terrain. It allows to determine the perfect height of each tracker pile in order to smooth the surface of the solar modules on the plant as much as possible and to reduce the need for grading. Consequently, mutual shading between tables is reduced, thereby reducing backtracking periods and optimizing the energy yield. In addition, it also avoids on-site piles cutting.

Image 1: piles optimization and surface smoothing

This study results in the creation of a piles booklet, a document in which the three dimensional positioning of each tracker pile on the plant is registered.

Image 2: example of a 3D layout with several solar trackers

Step 2: Implementing individual tracking during the construction phase

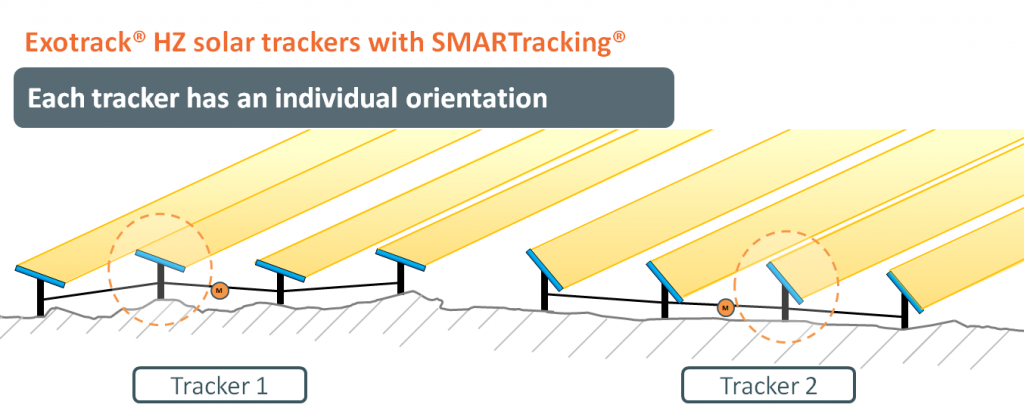

Once the piles are driven at the beginning of the construction phase, their real on-site positioning is collected and registered in a document, called as-built survey. The individual tracking program is then developed and implemented based on the registered values. This program corresponds to a custom routine within each motor control unit that includes a backtracking (panel on panel shade avoidance) strategy.

The tracking algorithm, implemented in the centralized PLC, calculates the optimized angle in real time and for every single motor. This angle is determined according to the exact location of the tables of a particular tracker and its neighbors.

Image 3. Example of the individual kinematics of two trackers.

(the orange circles indicate the critical table that defines the tracking angle of the tracker)

Each solar tracker has the best suited position at any moment of the day and its control is individualized, which maximizes received irradiation and improves the energy production compared to a global backtracking approach.

What’s more, the as-built survey is the basis for a gap analysis between the initial piles booklet and the real on-site positioning of the piles. This study aims to detect any default that could result in a mounting impossibility, thus avoiding potential loss of time.

SMARTracking is the result of this two-step process, each one leading to specific energy gains. The two steps are independent from each other.

Case study: SMARTracking on a 6.7-MWp PV plant project in France: a 5% additional production gain

Let’s now put real figures in terms of production and revenue gains on this patented two-step tracking process by looking at a 6.7-MWp PV plant project situated in South West France.

The below table summarizes the project data.

| Site location | South West France |

| Plant capacity | 6.7 MWp |

| Number of Exotrack HZ single-axis solar trackers | 48 |

| Annual energy yield | 8750 MWh/year |

| PV modules type | 72c Monocrystalline 315 Wp |

The table hereunder indicates the data related to the site topography.

| Local slopes | South Slope | East Slope | North/East Slope | South/East Slope |

| Minimum | -4.02% | -6.45% | -4.39% | -4.75% |

| Maximum | 4.58% | 7.51% | 5.78% | 6.46% |

| Average | 1.21% | 1.34% | 1.15% | 1.28% |

By implementing the SMARTracking process on this PV plant equipped with Exotrack HZ single-axis trackers, an additional 5% yield increase was achieved annually. This results in a revenue increase of $880,000 over 20 years, based on a PPA of 100 $/MWh. The below results were validated by an independent technical advisory firm, kiloWattsol.

| Production gains with SMARTracking | Irradiation gains | Production gains |

| Step 1. 3D Plant Layout Optimization | 1.8% | 2.1% (185 MWh/year) |

| Step 2. Individual tracking | 2.5% | 2.9% (255 MWh/year) |

| SMARTracking (step 1 & step 2) | 4.3% | 5% (440 MWh/year) |

| Revenue gains with SMARTracking | PPA example 1 | PPA example 2 | ||

| PPA | 100 $/MWh | 80 €/MWh | 62 $/MWh | 50 €/MWh |

| Yearly revenue increase thanks to SMARTracking | $44,000 | 35 000 € | $27,125 | 21 875 € |

| Revenue increase generated by SMARTracking over 20 years | $880,000 | 700 000 € | $542,000 | 437 000 € |