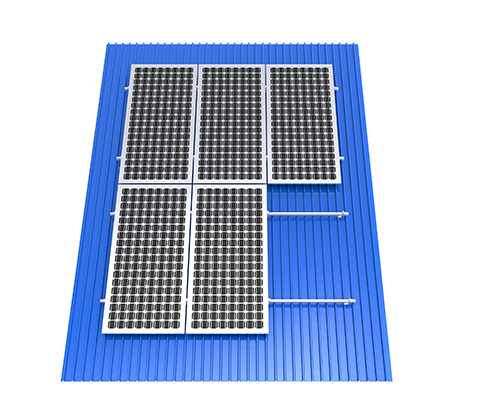

Metal roof aluminum Kliplok solar mount

Material: Typically high-strength, corrosion-resistant aluminum alloy (e.g., 6005-T5).

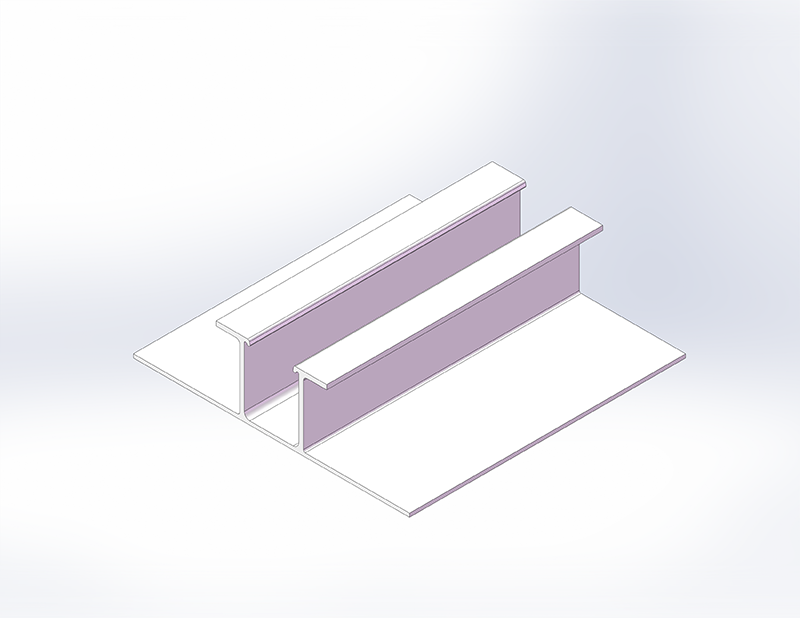

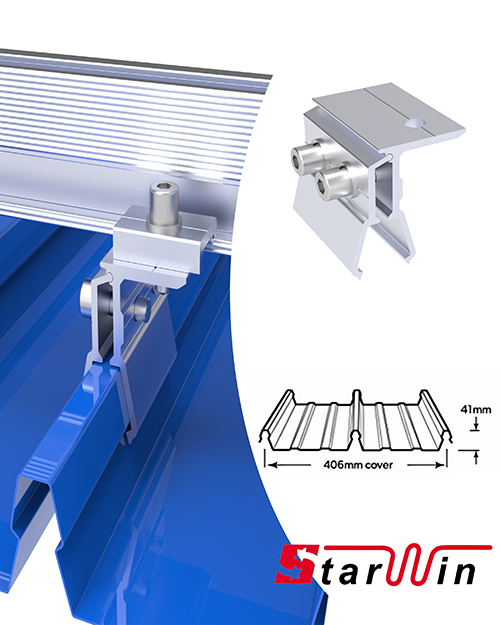

Design: A two-part assembly that wraps around the roof rib. The lower part sits under the rib, and the upper part bolts down from the top, creating a powerful mechanical grip.

Seal: Often incorporates an EPDM or rubber gasket between the clamp and the metal roof to prevent abrasion, dampen vibration, and provide a secondary seal.

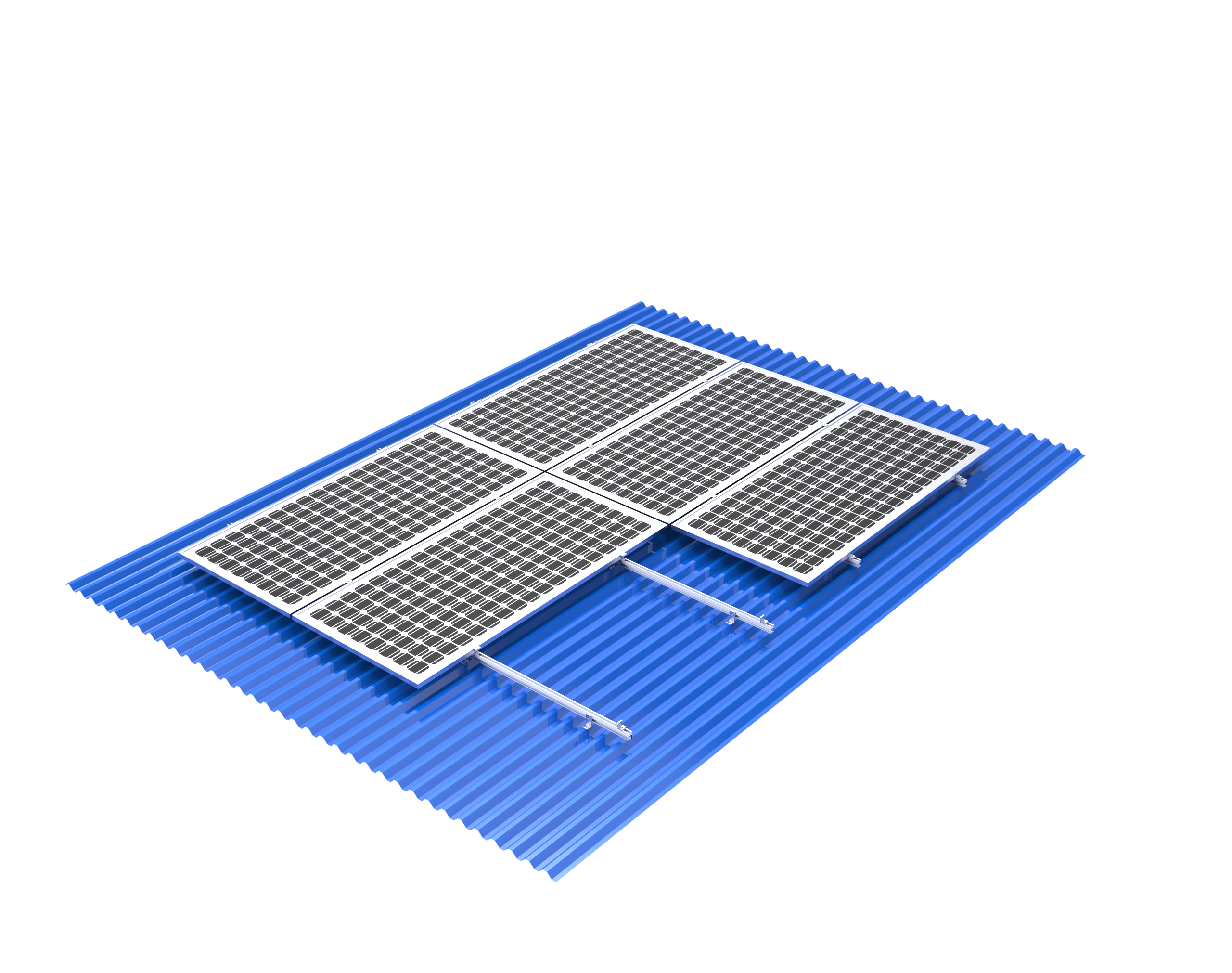

Extruded aluminum rails run perpendicular to the roof ribs. The solar panels are attached to these rails using standard panel clamps

Rails are lightweight, strong, and corrosion-resistant, matching the long lifespan of the roof and solar panels.

Advantages and Benefits

The primary benefit. By avoiding penetrations in the roof sheet's field, it eliminates the primary source of potential leaks, warranty issues, and corrosion.

No drilling into the roof deck means quicker installation, less noise, and no metal swarf left on the roof that could cause rust stains.

Aluminum components are compatible with most standard color-coated (painted) steel or aluminum roofs, preventing galvanic corrosion.

Perfect for warehouses, factories, and agricultural buildings with long, uninterrupted metal roof spans.

Wind Uplift Calculations: Especially in high-wind or cyclonic regions, detailed engineering is required to determine the correct clamp spacing and the potential need for supplemental through-bolt attachments at strategic points.