As the solar industry continues to evolve, vertical solar mounting systems have emerged as an innovative and space-efficient solution for maximizing energy generation in areas with limited installation space. Unlike traditional ground-mounted or rooftop systems, vertical mounts position the solar panels upright—offering unique advantages in terms of land use, aesthetics, and bifacial energy gain.

In this article, we’ll explore everything you need to know about vertical solar mounting systems — including their design, applications, and key benefits — as well as how Starwin Solar’s customized vertical racking solutions can help you create a smarter and more sustainable project.

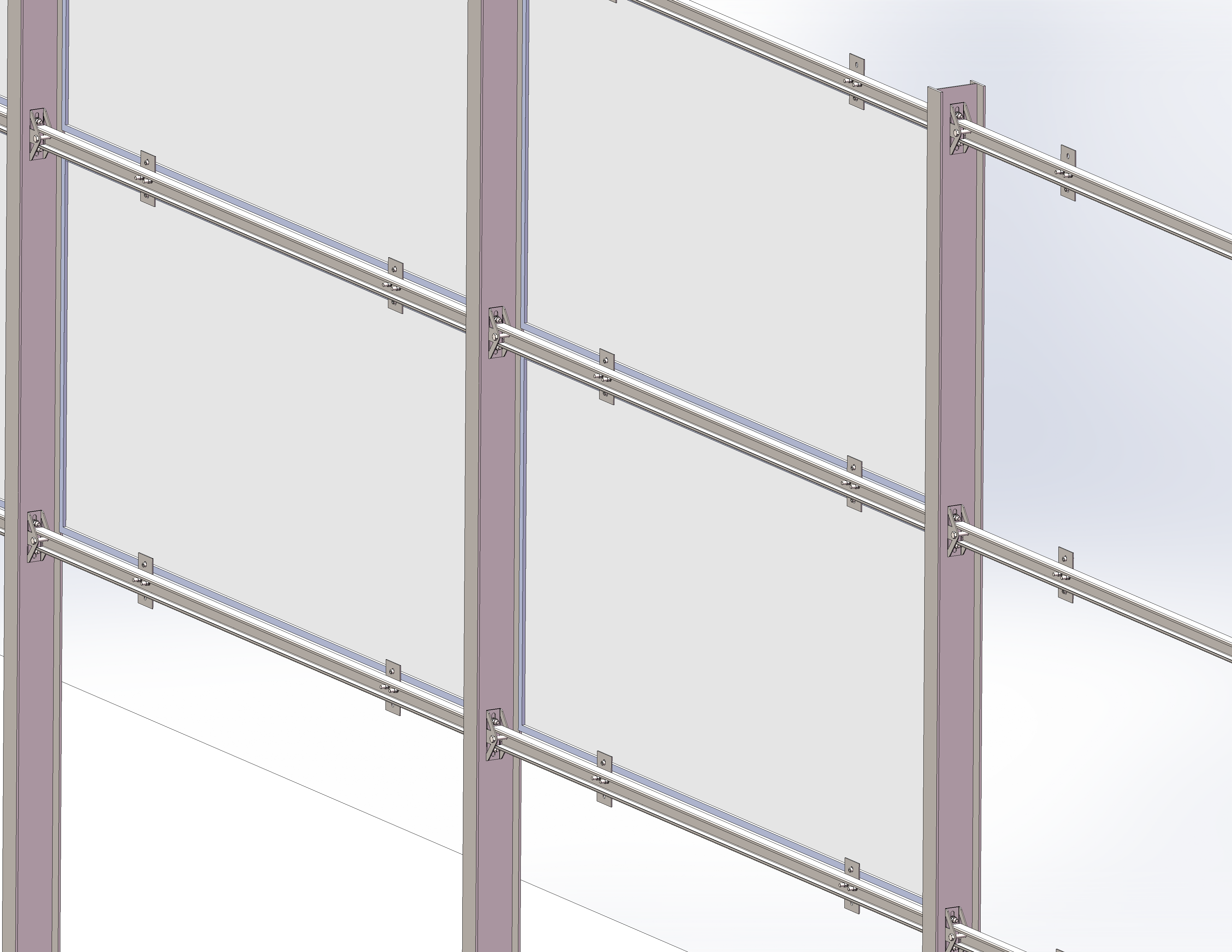

1. What Is a Vertical Solar Mounting System?

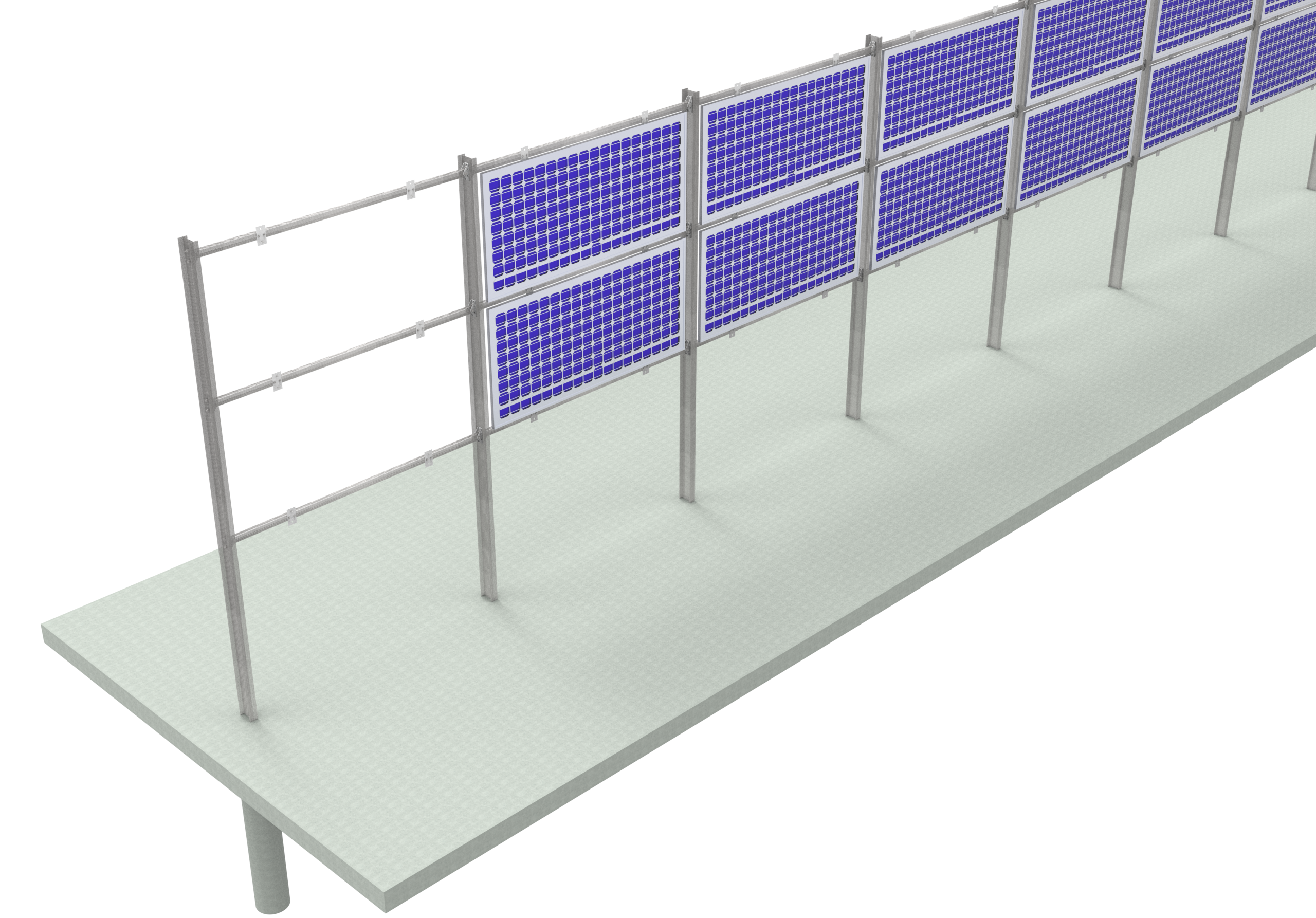

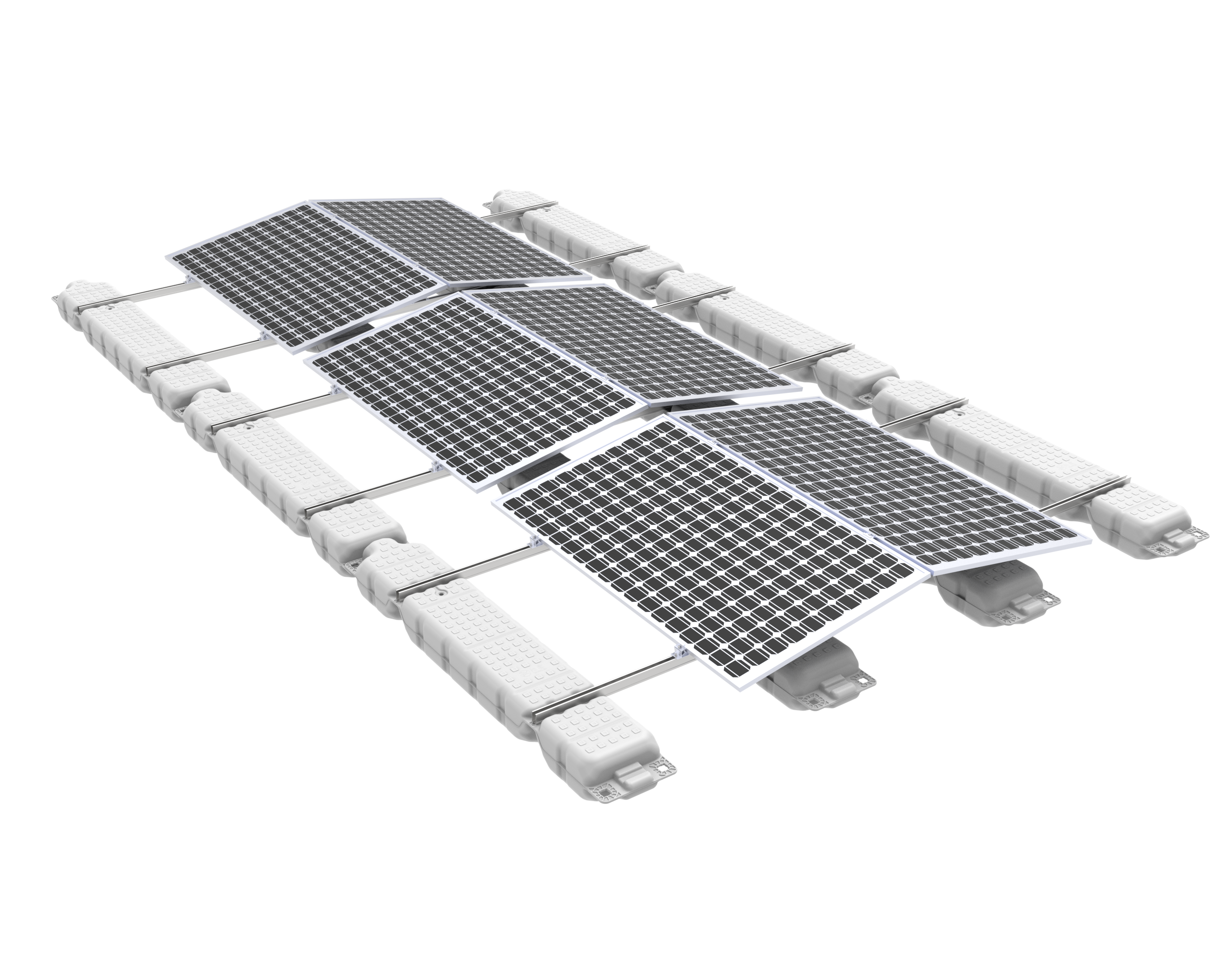

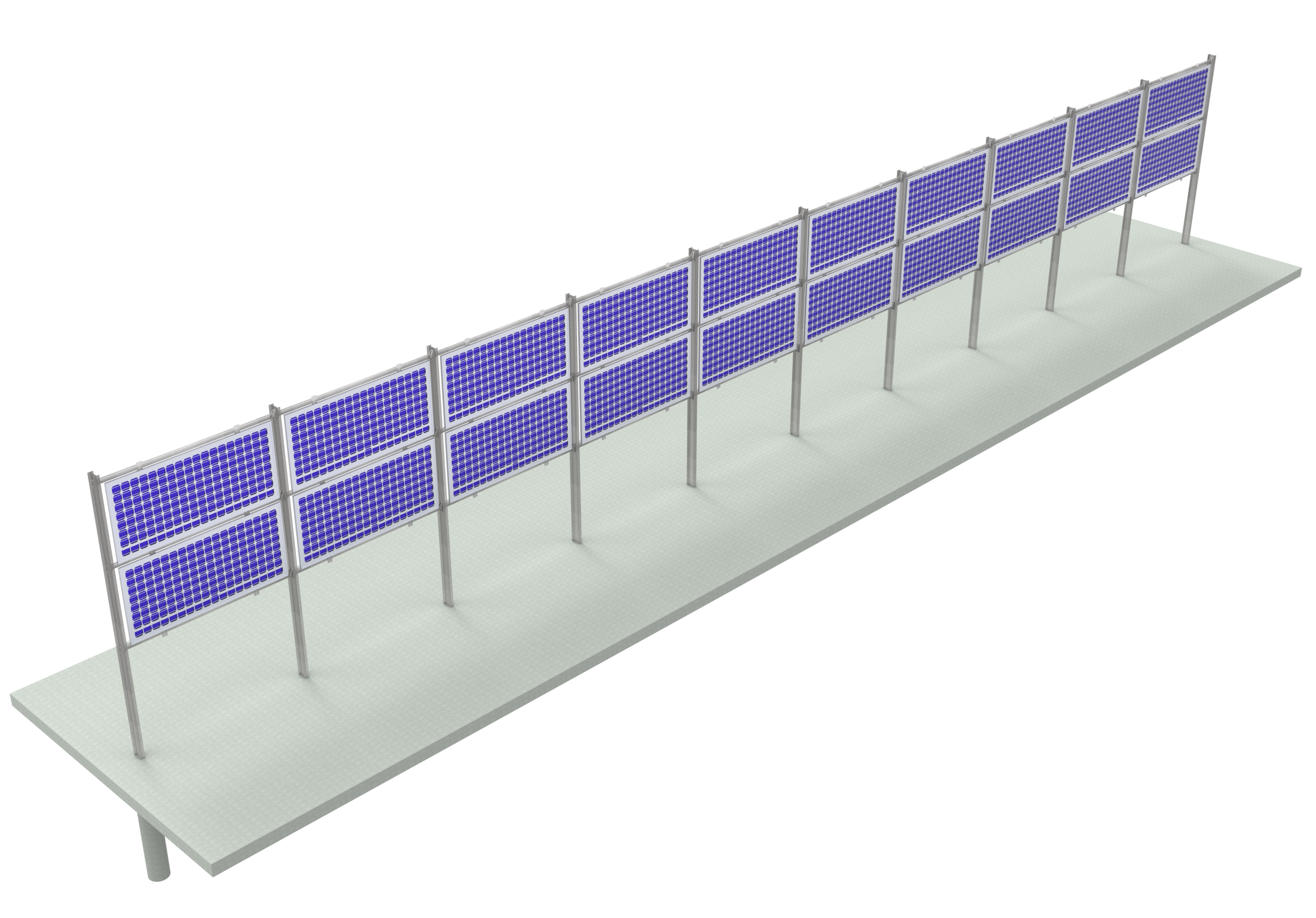

A vertical solar mounting system is a racking structure that supports solar panels installed upright, perpendicular to the ground. This layout is often used for bifacial solar modules, which can absorb sunlight from both sides, maximizing energy yield throughout the day. Instead of traditional tilted arrays, vertical mounts are typically aligned east–west, enabling them to capture sunlight from both morning and afternoon angles. This makes them ideal for regions with high albedo surfaces (like snow or light-colored ground) or limited space scenarios, such as fences, walls, or agricultural boundaries.

2. Key Components of a Vertical Solar Mounting System

A vertical solar racking system usually includes:

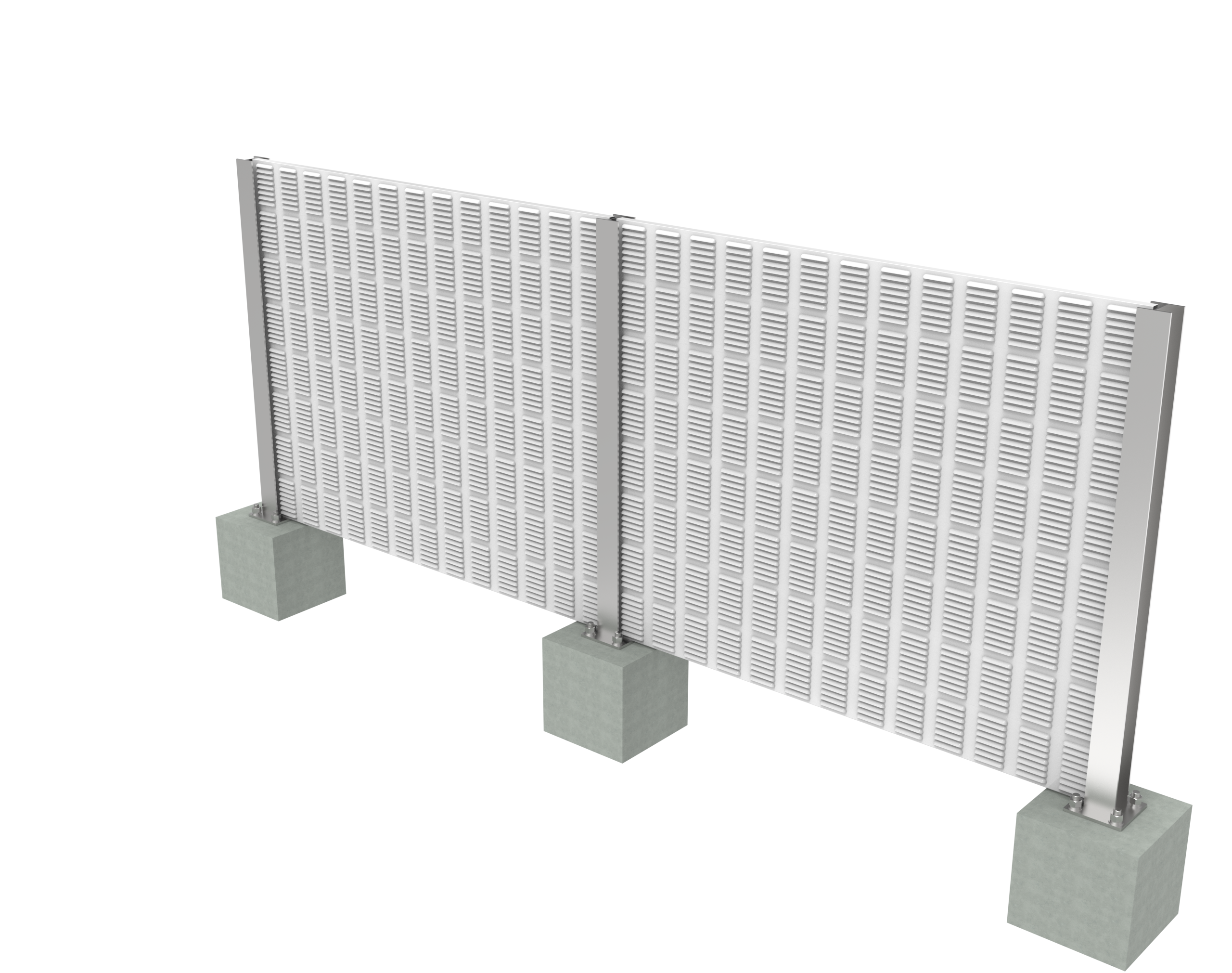

Support posts: Typically made from galvanized steel or aluminum to ensure durability and corrosion resistance.

Mounting rails: Horizontal rails fixed between the posts to hold the solar panels securely.

Mid and end clamps: Used to fix solar modules tightly and safely.

Fasteners and grounding parts: For easy installation and electrical safety.

At Starwin Solar, our vertical systems are designed for quick installation and long-term reliability. We use high-strength anodized aluminum (AL6005-T5) and hot-dip galvanized steel (Q235B) to ensure long-term durability in standard outdoor environments to ensure long-term durability in typical outdoor environments — however, this type of vertical mounting is not recommended for high-wind regions.

3. Advantages of Vertical Solar Mounting Systems

Space Efficiency

Vertical mounting is perfect for areas where land space is limited. It can be used along fences, walkways, or perimeters without interfering with daily operations.

Ideal for Bifacial Modules

When paired with bifacial panels, vertical systems can harvest reflected sunlight from both sides, increasing total power generation—especially in snowy or reflective environments.

Easy Maintenance

Panels are easier to clean and inspect since they are upright and accessible from both sides. There’s also minimal dust accumulation compared to tilted installations.

Aesthetic Design

Vertical arrays can be visually appealing, serving dual purposes as fencing walls or boundary partitions while generating clean energy.

Cost-Effective Installation

With simplified foundations and fewer supporting parts, vertical solar structures can reduce both installation time and labor costs.

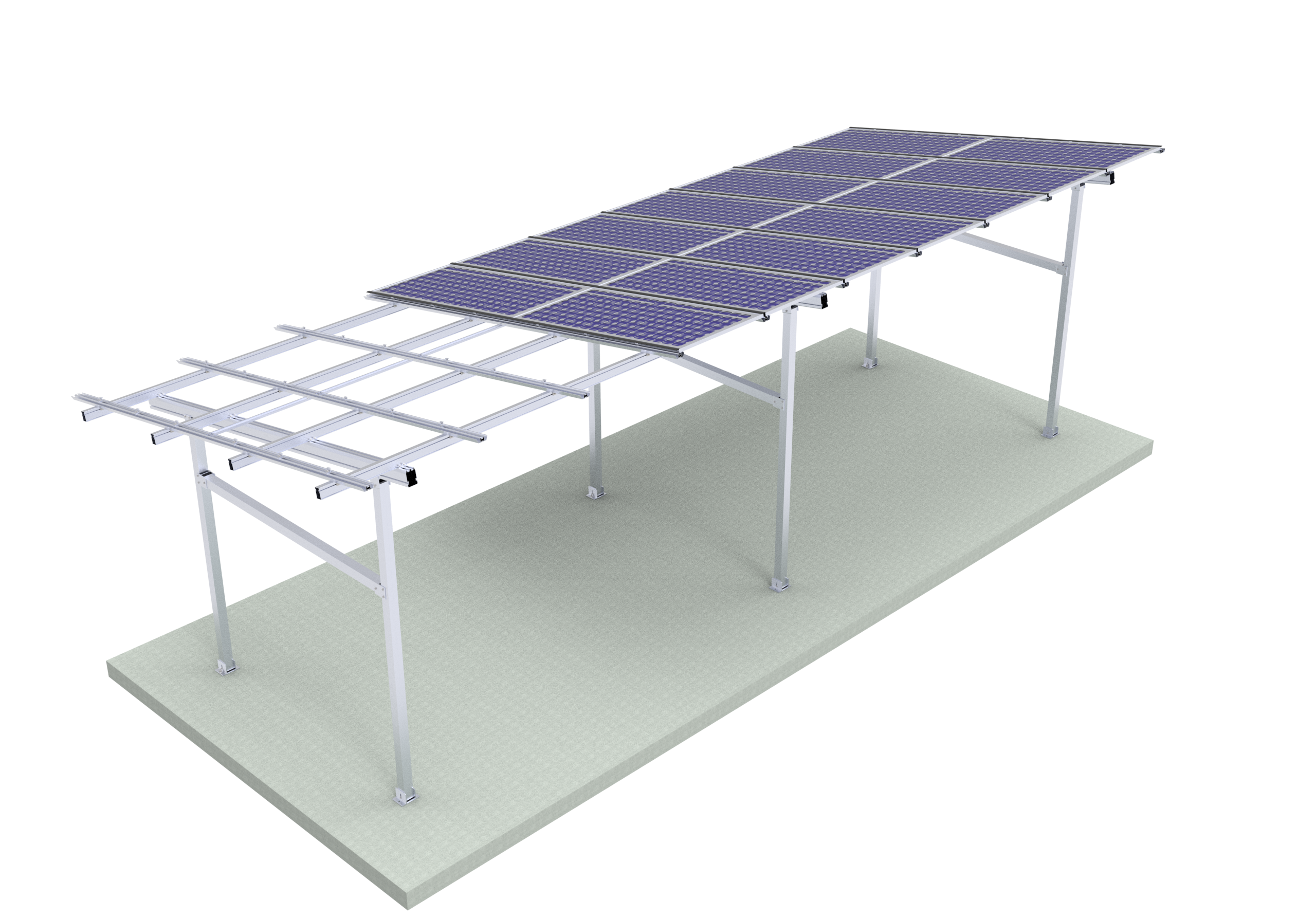

4. Typical Applications

Vertical solar mounting systems are incredibly versatile. Here are some of the most common applications:

Solar Fences: Combine security fencing with power generation.

Agrivoltaic Systems: Perfect for farms, where panels can be installed along the edges of farmland.

Highway or Railway Barriers: Generate electricity while serving as noise or wind barriers.

Building or Industrial Boundaries: Improve land utilization and site aesthetics.

Snowy or Desert Regions: Maximize bifacial gain from ground reflection.

5. Installation and Design Considerations

When designing a vertical solar structure, engineers consider several factors:

Orientation: East–west alignment ensures balanced generation across the day.

Ground clearance: Typically 0.3–0.5m for bifacial optimization and cleaning access.

Wind load: Vertical panels experience different aerodynamic forces; structural design must ensure stability under local wind conditions.

This system is generally not recommended for installation in regions with extremely high wind speeds or frequent typhoons.Foundation type: Ground screws, concrete footings, or driven piles depending on soil conditions.

Starwin Solar provides customized engineering designs for each project, based on module size, local weather data, and installation site conditions. Our professional design team can deliver 3D drawings, structural calculations, and full BOM lists within a short lead time.

6. Why Choose Starwin Solar’s Vertical Mounting System

No Minimum Order Quantity (MOQ) – Whether you need one sample set or a full container, we can supply flexibly.

Free Sample Service – For testing and compatibility checks.

Customizable Design – Tailored for your module layout and project needs.

Fast Lead Time – Typically within 7–15 days after confirmation.

Durable & Corrosion-Resistant Materials – Designed for long-term outdoor performance.

Our vertical solar mounting systems are compatible with all standard framed modules and meet international standards such as AS/NZS 1170, JIS C8955, and ISO 9001.

With years of experience serving global solar installers and EPCs, Starwin Solar is committed to providing reliable racking solutions that make solar projects easier, faster, and more efficient.

7. Conclusion

Vertical solar mounting systems are redefining how we think about solar energy deployment. From maximizing space use to improving bifacial performance, these systems offer a practical and aesthetically pleasing solution for modern solar projects. If you’re planning a solar project that requires a compact, durable, and visually appealing racking solution, Starwin Solar’s vertical mounting system is your ideal choice.

Contact us today to get a free design and quotation — and let’s make your next project stand tall with clean, renewable energy.