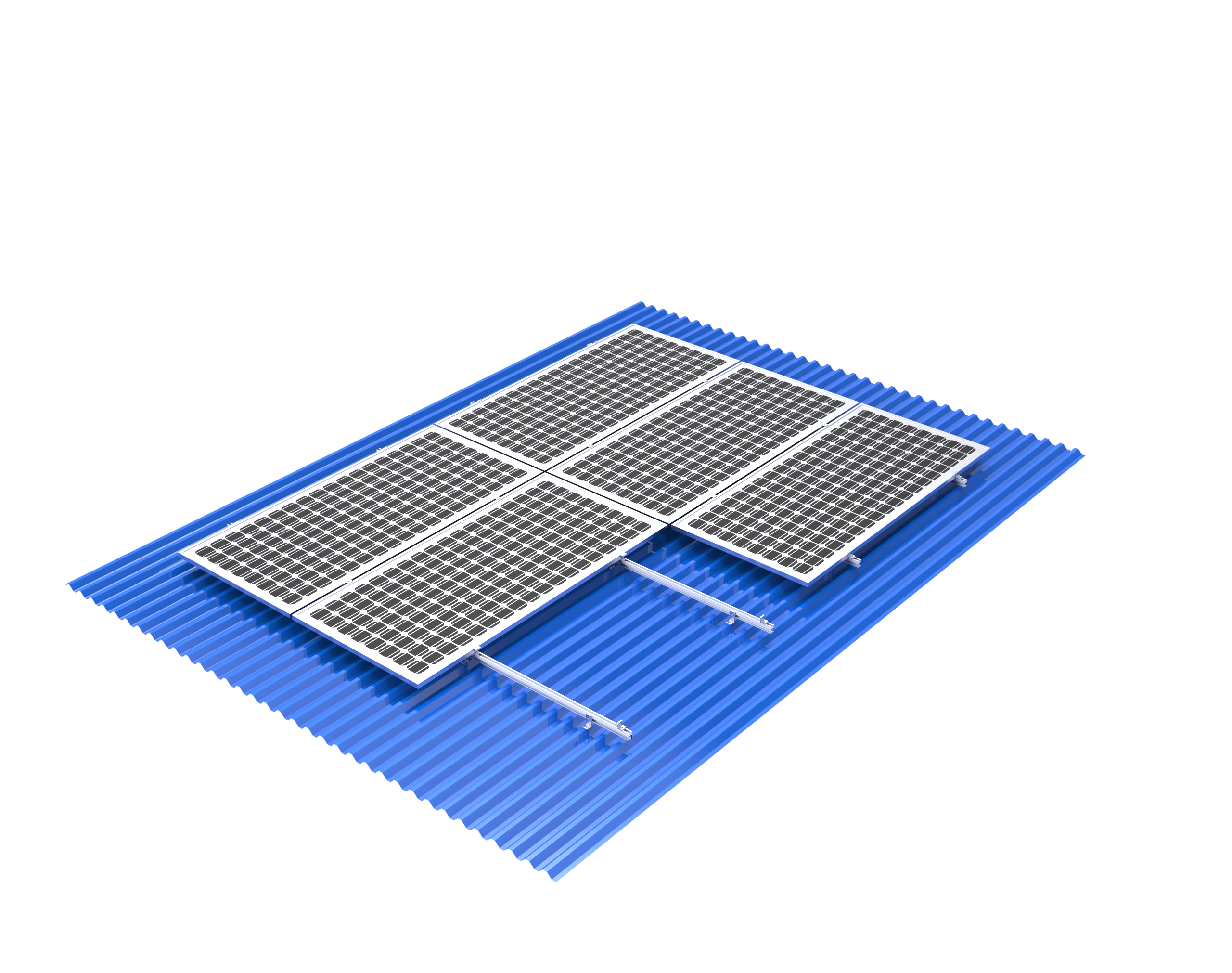

Teach you to choose the right solar photovoltaic structures

With the rapid development of my country's green economy, monocrystalline silicon/polycrystalline silicon <strong "keylink"> photovoltaic power generation and thin-film BIPV technologies are becoming more mature. Compared with other structures, steel structure has huge advantages in terms of use function, design, construction and comprehensive cost. Therefore, it is of great significance to actively develop and produce new steel structure <strong "keylink"> photovoltaic support system to replace the existing angle steel photovoltaic support system.

1. Types of steel used for solar steel photovoltaic support

At present, in view of the simple structure and small size of solar photovoltaic support, light structural steel and small-section ordinary steel are mainly used in the selection of steel materials.

Light structural steel

Light structural steel: Light structural steel mainly refers to round steel, small angle steel and thin-walled steel.

1) Angle steel

Advantages: When angle steel is used as a supporting member, it can make better use of the strength of the steel and facilitate the installation of the overall bracket.

Disadvantages: When angle steel is used as a bending and compression member, the deformation produced is relatively large.

2) Thin-walled steel

Advantages: Compared with hot-rolled steel, the radius of gyration of thin-walled steel can be increased by 50-60% under the same cross-section, and the moment of inertia and resistance of the section can be increased by 0.5-3 times, so it can be used more reasonably The strength of the material.

Disadvantages: Because the processing of thin-walled steel is mostly in the factory, high-precision drilling is required to match the screw holes behind the photovoltaic panel. Hot-dip galvanizing can be used to prevent rust after the drill is drilled in the factory; when it is transported to the site for installation, it is difficult to operate the tools due to the small cross-section of the steel, and the construction is more difficult.

3) Round steel

Round steel refers to a solid long steel with a circular cross section. The difference between round steel and other steel bars:

a. The appearance is different. The round steel has a smooth appearance, no grains and no ribs. Other steel bars have carved or ribbed appearances. This will result in a small bonding force between the round steel and concrete, while other steel bars and concrete Great adhesion.

b. The composition is different. Round steel (first-grade steel) belongs to ordinary low-carbon steel, and most of the other steel bars are alloy steel.

c. The strength is different, and the round steel has low strength.

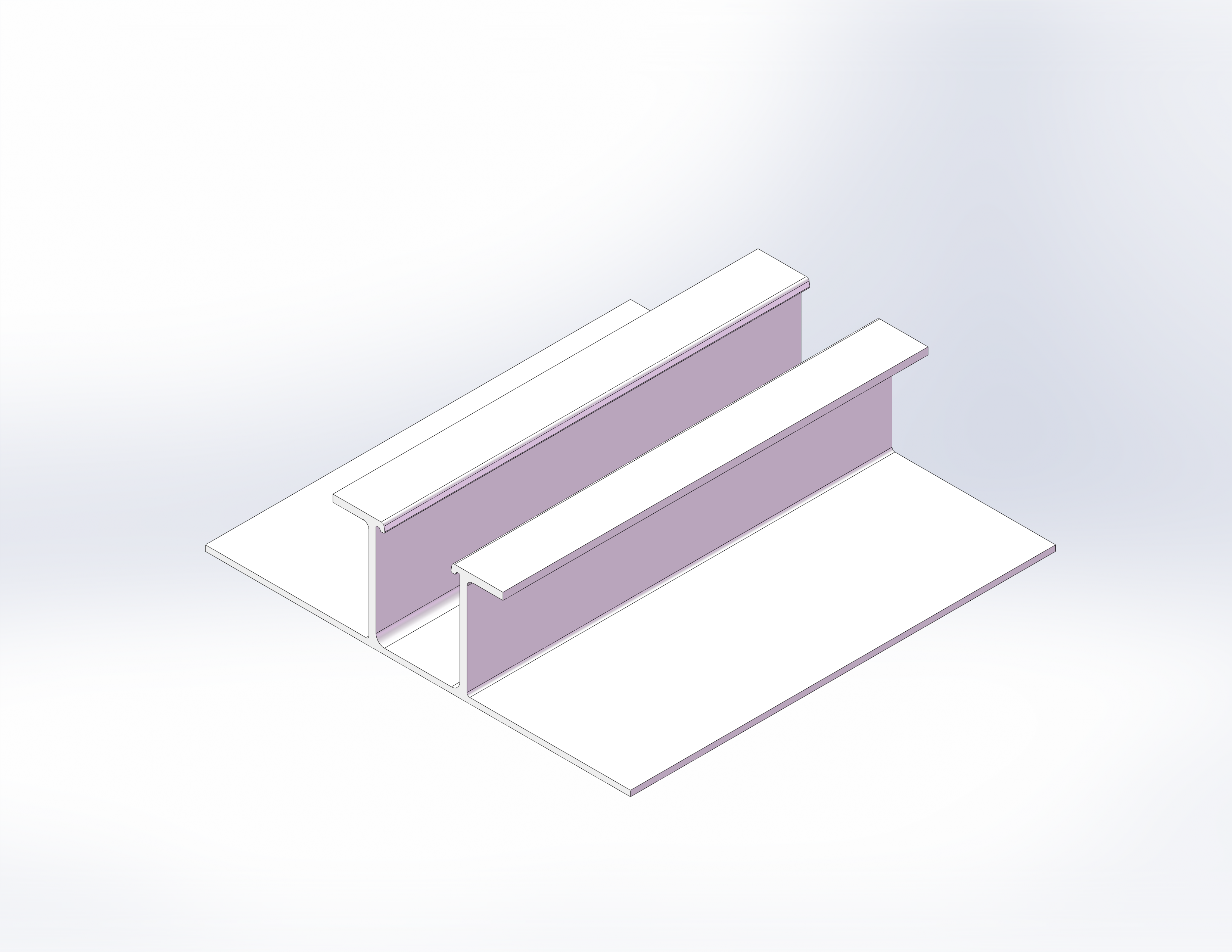

2. Ordinary steel

Ordinary steels often use carbon structural steels or low-alloy steels that are easy to smelt and low in cost. There are many types of cross-sections. Commonly used photovoltaics mainly include I-shaped, H-shaped, L-shaped and various design requirements.

2. Requirements for the performance of steel in solar photovoltaic brackets

1) Tensile strength and yield point.

The high yield point can reduce the cross-section of section steel components, reduce the weight of the structure, save steel, and reduce the overall project cost.

The high tensile strength can increase the overall safety reserve of the structure and improve the reliability of the structure.

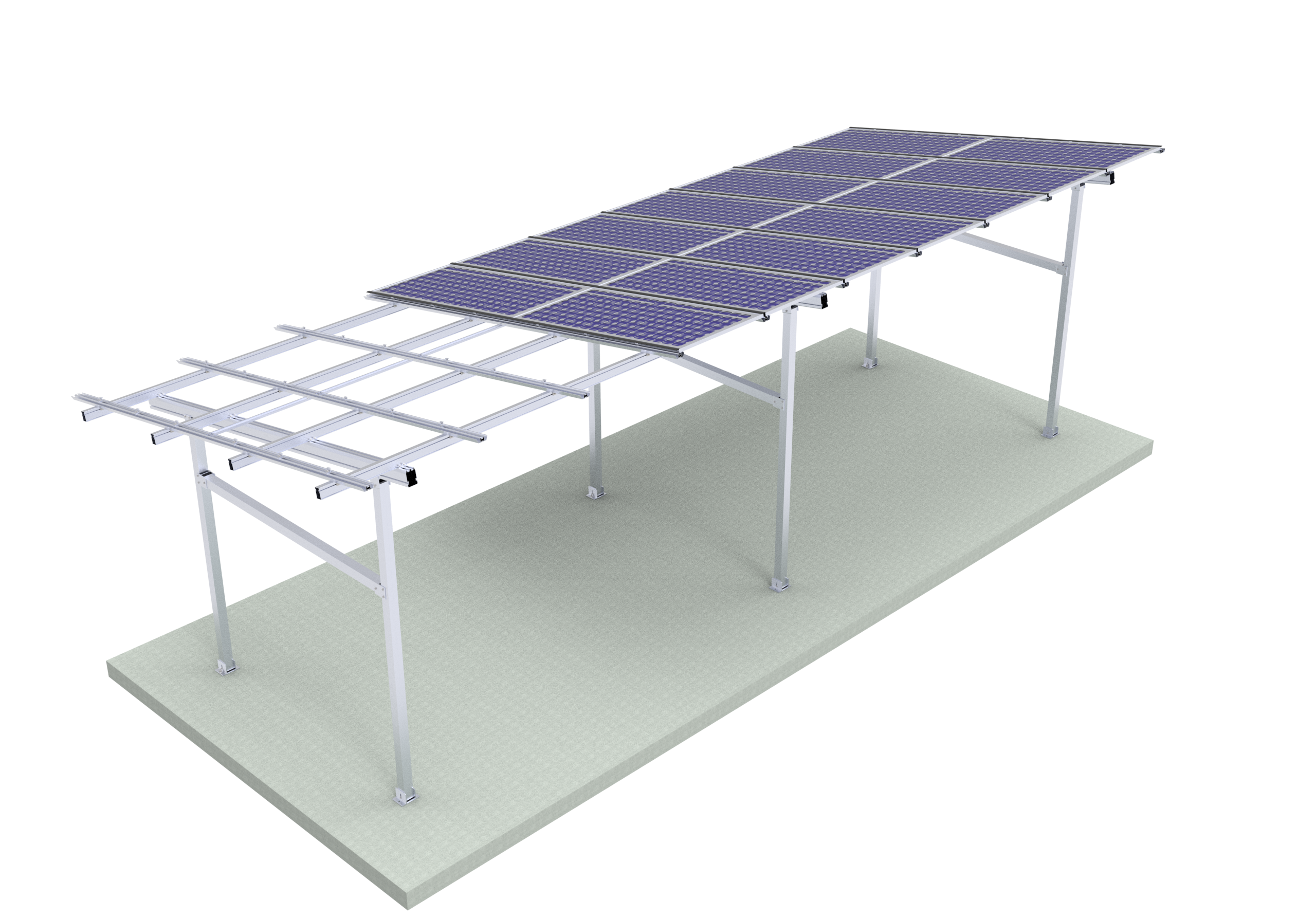

Finally, Aluminum solar racks are light and beautiful. the strength is also enough .

more and more customers choose aluminum solar mounting structures .