We will make unremitting effort to innovate,promote the PV industry,are endeavor or make green energy cheap.

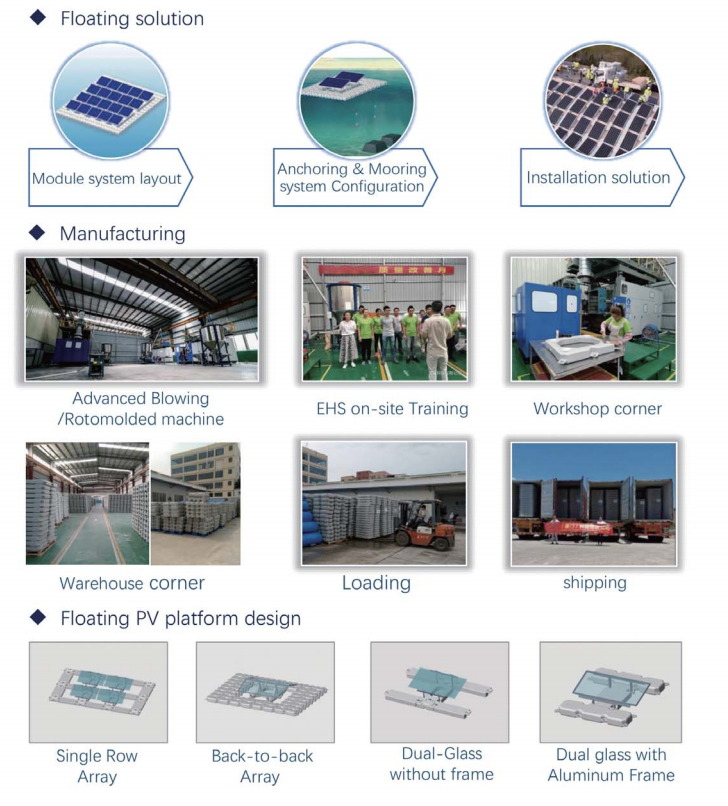

Floating Structure (The Pontoon/Hull):

This is the foundation that provides buoyancy. The two primary designs are:

Pontoon-Based (Modular Floats): Individual, often HDPE (High-Density Polyethylene) floats are connected like a large raft. Each float holds one or a few panels. This is the most common design due to its modularity and ease of transport/installation.

Membrane-Based: A flexible, reinforced plastic membrane is stretched across a floating frame. The panels are mounted on top of this membrane. This design can cover large areas more continuously.

Mounting Structure:Similar to ground mounts, this is the frame that holds the panels at the correct angle. It is either integrated into the float or attached on top of it. Materials are typically aluminum or hot-dip galvanized steel for high corrosion resistance.

Anchors: These are placed on the bed of the waterbody. Types include deadweight anchors (concrete blocks), screw anchors (for softer beds), and drag-embedded anchors.

Mooring Lines: High-strength, UV-resistant ropes (e.g., nylon, polyester) or chains connect the floating structure to the anchors.

System Design: The mooring can be a spread mooring (multiple anchor points) or a tension-leg mooring (using buoyancy to keep lines taut), which is common in deeper waters.

Underwater Cable Management:Special submersible, rodent-proof DC cables connect the arrays. These cables are designed to withstand long-term UV exposure and immersion. They are held in place by cable trays or floating pontoons to prevent tangling and damage.

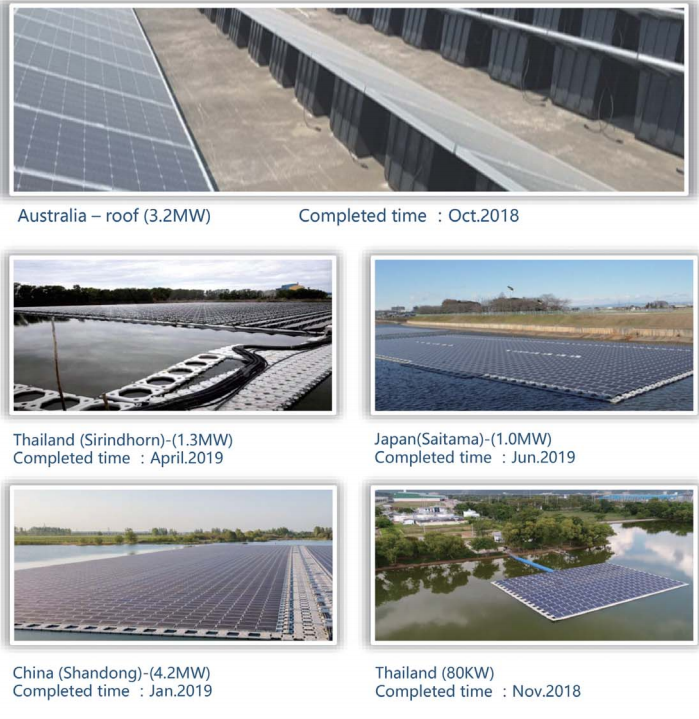

Application: Industrial water pool,lake,aquaculture farm, water ponds etc.