Concrete Foundation Aluminum Ground Mount: The Smart Choice for Modern Solar Installations

As the global demand for renewable energy grows, solar power continues to lead the way. For installations where rooftop mounting isn’t an option or large-scale energy generation is the goal, ground-mounted solar systems are the ideal solution. Among the most efficient and sustainable choices today is the concrete foundation aluminum ground mount system—an option that balances structural strength, corrosion resistance, and ease of installation.

In this article, we’ll explore the key benefits of aluminum ground mounts with concrete foundations, break down their installation considerations, and compare fixed and tracking systems to help you make informed project decisions.

If you're considering high-performance aluminum ground solutions for your solar project, don't miss our PV aluminum ground mount products, trusted in real-world solar installations across a wide range of conditions.

Why Choose Concrete Foundation Aluminum Ground Mount Systems?

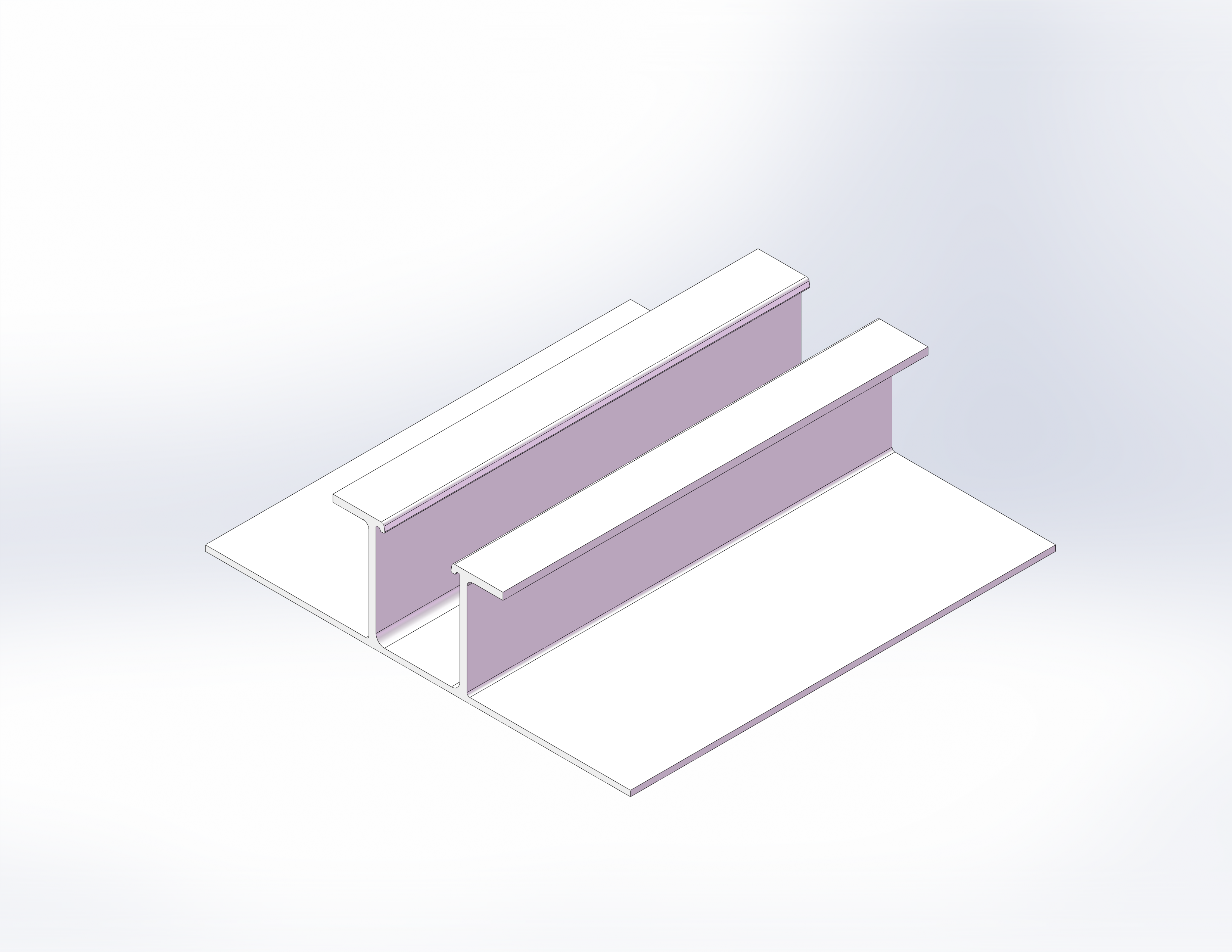

Lightweight Yet Strong Structural Design

Aluminum ground mount systems are favored for their lightweight nature, which makes them easier to transport, handle, and install. When paired with a concrete foundation, they offer exceptional stability even in areas with challenging soil or extreme weather conditions. The reduced weight of aluminum does not compromise its strength—extruded aluminum profiles are engineered for high load-bearing capacity while minimizing material use.

This combination of lightness and structural reliability allows for quicker on-site assembly and reduced labor costs. Additionally, aluminum’s high resistance to corrosion ensures that your solar mounting structure maintains integrity over decades, especially in humid or coastal environments where steel may degrade more quickly.

Corrosion Resistance for Long-Term Performance

One of the key advantages of aluminum is its natural resistance to corrosion. Unlike untreated steel, aluminum forms a protective oxide layer that defends against rust and environmental wear. This makes concrete foundation aluminum ground mount systems an ideal choice for long-lasting solar installations with minimal maintenance requirements.

This corrosion resistance not only enhances durability but also ensures electrical grounding reliability, as aluminum maintains conductivity better than rusted steel. These properties are particularly valuable in agricultural or off-grid settings where access to regular maintenance may be limited.

Installation Considerations for Aluminum Ground Mount Systems

Preparing the Concrete Foundation

Before any aluminum racking is installed, a solid concrete base must be constructed. This includes conducting a geotechnical analysis to determine the required footing size, depth, and type—whether spread footings, piers, or slab-on-grade. Concrete foundations provide a stable platform for aluminum structures, ensuring they remain secure under wind, snow, and seismic loads.

Formwork is placed, concrete is poured, and anchor bolts or sleeves are embedded accurately to align with the mounting system. Once cured, the foundation provides a robust, permanent base that minimizes the risk of structural shift or settling over time.

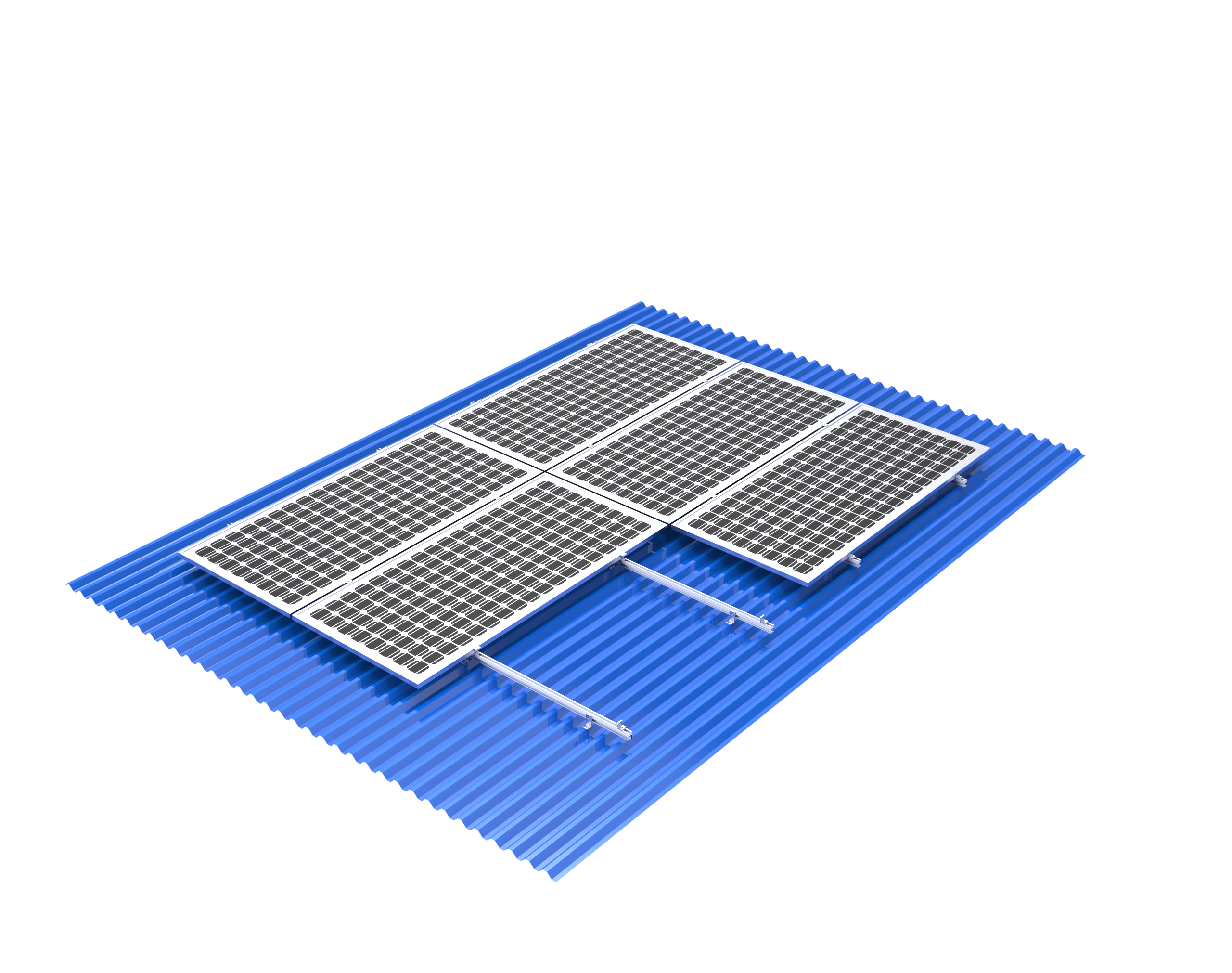

Mounting and Alignment Process

After the foundation is ready, the aluminum racking system is mounted using adjustable base plates or pre-drilled fixtures. Aluminum’s light weight enables installers to align and secure the components with greater ease than heavier steel systems. Precision alignment is crucial to optimize solar panel orientation and maximize power output.

Modules can be mounted in landscape or portrait orientation, and the modular nature of aluminum systems allows easy expansion or adaptation to different site layouts. Moreover, the combination of aluminum frames with concrete footing delivers a high-performance system with a clean, modern appearance—an aesthetic edge for commercial or public-facing installations.

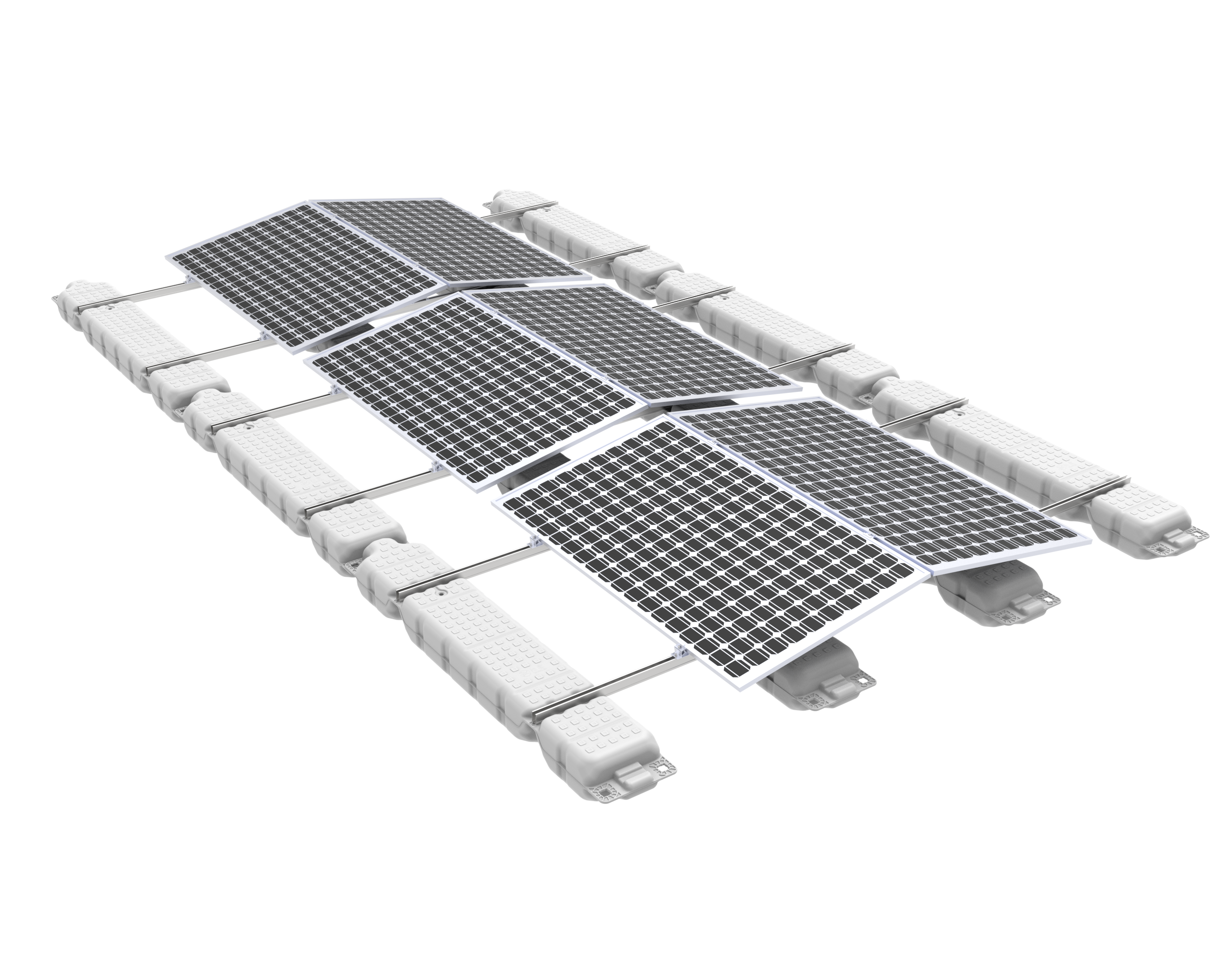

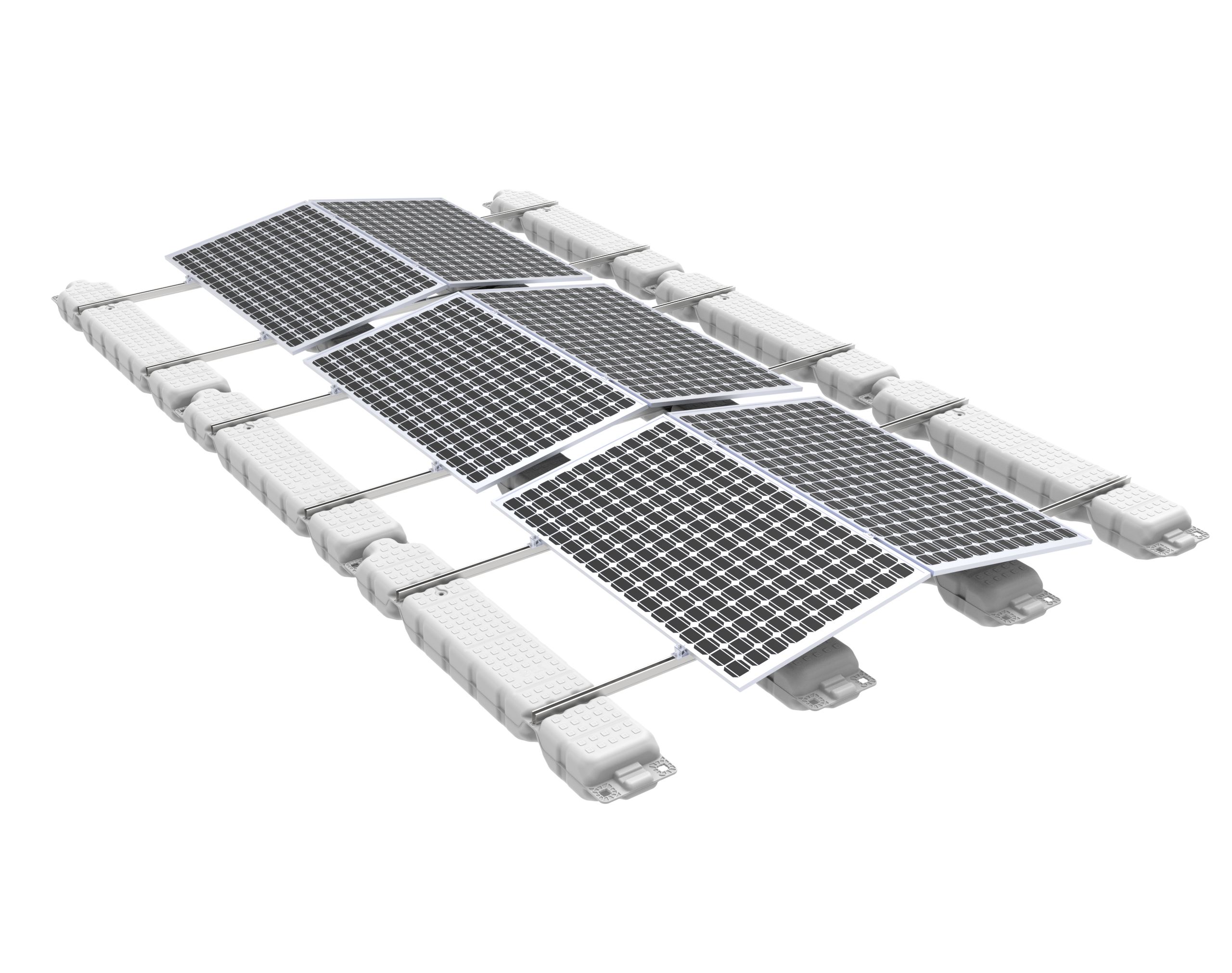

Types of Aluminum Ground Mount Systems

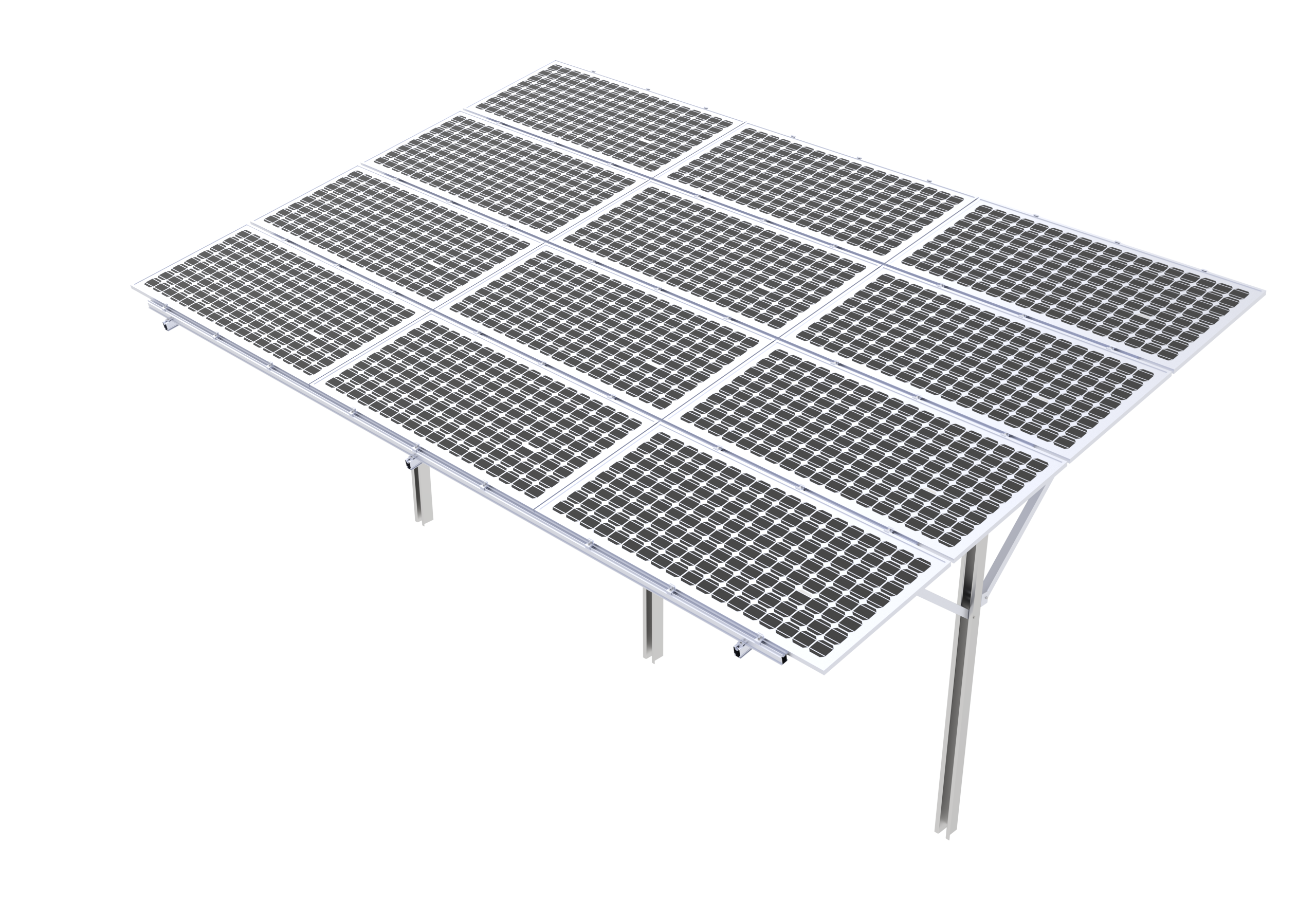

Fixed-Tilt Ground Mounts

Fixed-tilt systems are the most widely used configuration for aluminum ground mounts. These structures are designed with a set tilt angle optimized for local solar conditions and are anchored firmly to the concrete base. Fixed systems are cost-effective, reliable, and simple to maintain—making them ideal for projects where budget and stability are top priorities.

Thanks to the modular design of aluminum racking, fixed-tilt mounts can be installed rapidly with minimal on-site fabrication. This not only reduces labor costs but also helps meet project deadlines, especially important in utility or government-funded solar initiatives.

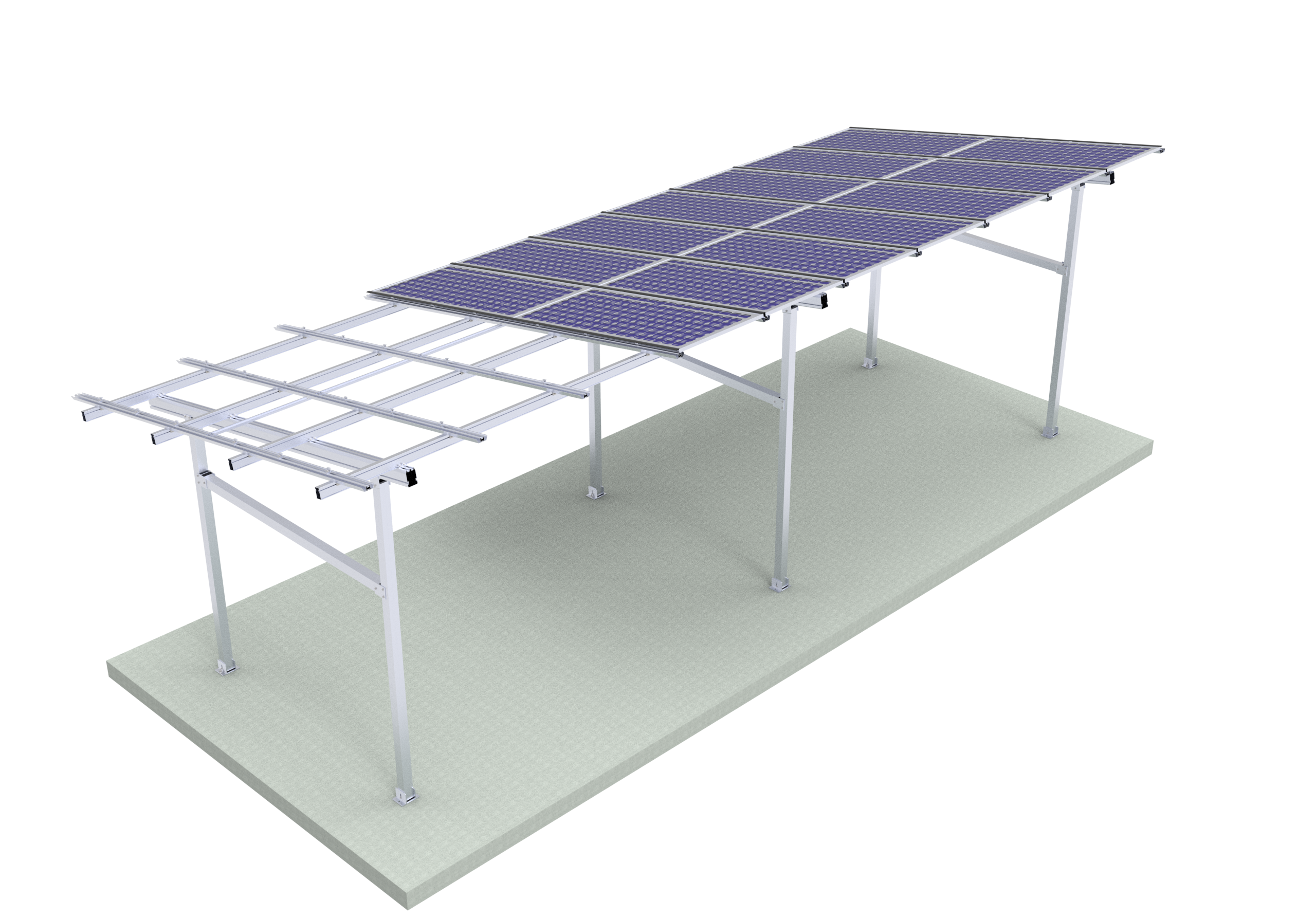

Tracking Ground Mounts

For projects seeking to maximize energy production, tracking aluminum ground mounts offer a dynamic solution. Single-axis trackers follow the sun’s path from east to west, while dual-axis trackers also adjust for elevation. Although more complex and slightly higher in cost, tracking systems can boost solar output by up to 35% compared to fixed installations.

Aluminum’s strength-to-weight ratio is a perfect match for these moving systems, reducing the mechanical stress on motors and bearings. When mounted on concrete foundations, these tracking systems gain additional stability, allowing them to operate smoothly in high-wind or uneven terrain environments.

Applications of Aluminum Ground Mount Systems

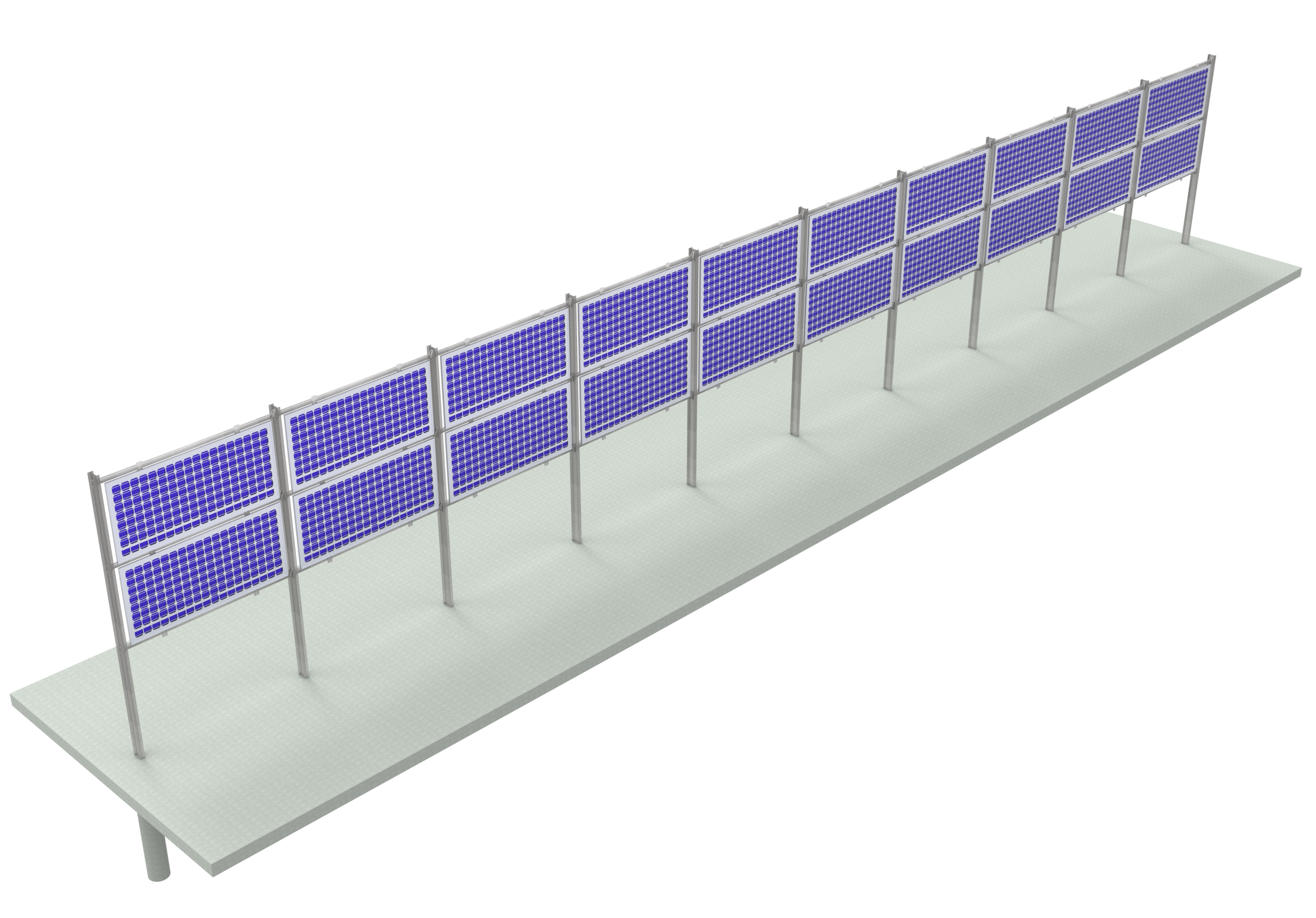

Commercial and Utility-Scale Installations

Concrete foundation aluminum ground mount systems are increasingly used in commercial and utility-scale solar projects due to their efficiency, durability, and scalable design. They support large PV arrays with minimal land disruption and can be custom-engineered to suit various terrains and environmental conditions.

From solar farms to industrial complexes, aluminum ground mounts deliver a high-performance structure capable of withstanding years of exposure while maintaining optimal panel alignment.

Agricultural and Off-Grid Applications

Aluminum ground mounts are especially suitable for agricultural settings, where they can be integrated into farmland, vineyards, or livestock areas. Their lightweight profile means less disruption to the land, and their corrosion resistance is ideal for areas with irrigation, fertilizers, and natural wear.

In off-grid or remote installations, where access to tools and heavy machinery is limited, aluminum systems offer unmatched ease of deployment. Their minimal maintenance needs also make them a dependable choice in these rugged environments.