Why Aluminum is the Dominant Choice for Metal Roof Mounting

Aluminum has become the industry standard for residential and  comercial metal roof solar mounts for several critical reasons:

comercial metal roof solar mounts for several critical reasons:

1.Exceptional Corrosion Resistance: This is the primary advantage. Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to rust and corrosion. This is crucial for a system intended to last 25-40 years on a roof exposed to rain, snow, and salty coastal air.

2.High Strength-to-Weight Ratio: Aluminum structures are very strong yet lightweight. This minimizes the additional dead load on the roof structure, a key engineering consideration. It also makes the components easier for installers to handle, improving safety and efficiency.

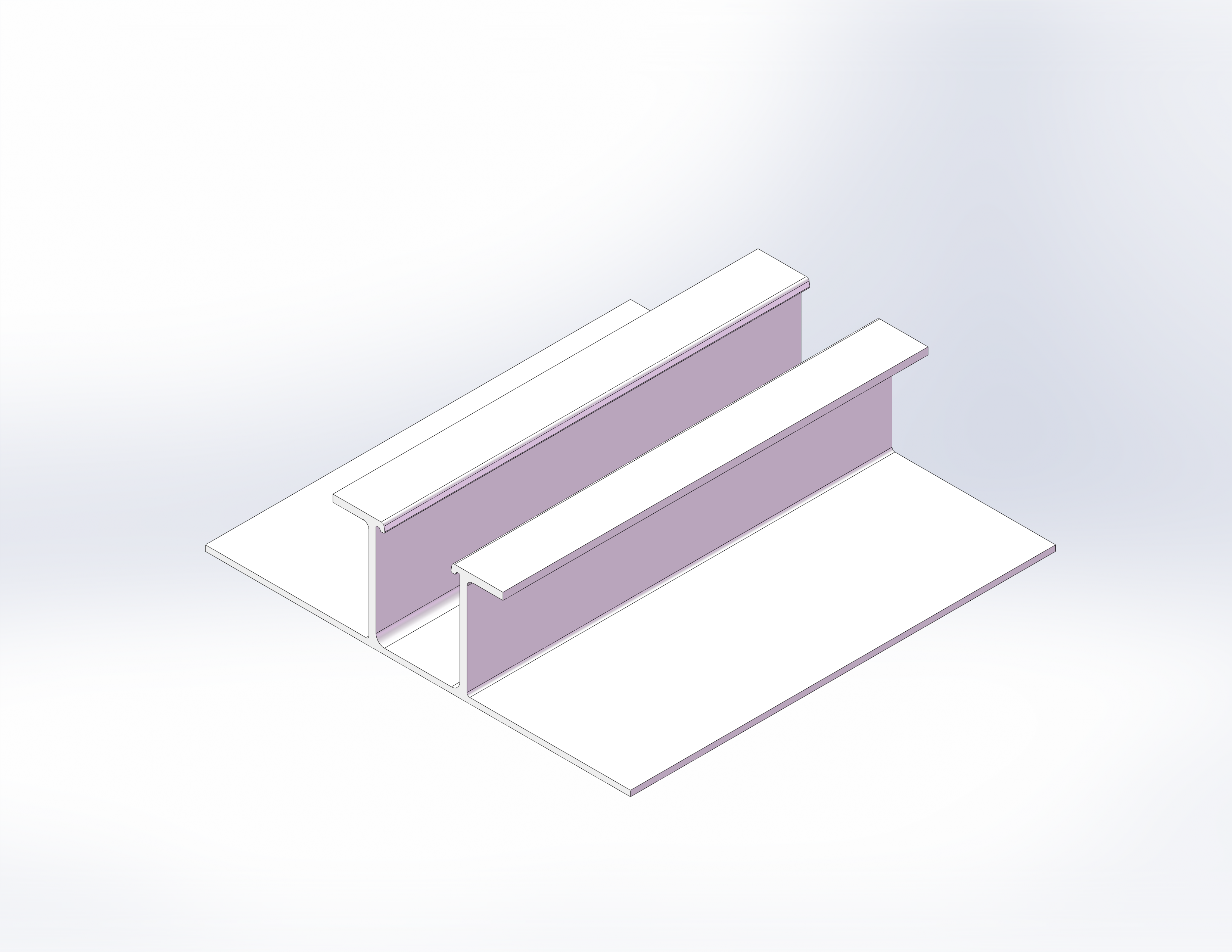

3.Non-Galvanic Corrosion Compatibility: When two dissimilar metals touch in the presence of an electrolyte (like water), they can create a galvanic reaction that corrodes the more active metal. Aluminum and the most common metal roofing material—Galvalume (steel coated with an aluminum-zinc alloy)—are relatively close on the galvanic series. When proper installation practices are followed (using compatible clamps and often with a separator pad), the risk of significant galvanic corrosion is very low. This is a major advantage over steel mounts on a metal roof.

4.Durability and Longevity: High-quality aluminum alloys (like 6005-T5 and 6061-T6) used in solar mounting are designed to withstand decades of UV exposure, temperature swings, and high wind loads without significant degradation.

5.Recyclability: At the end of its life, the aluminum mounting system is 100% recyclable, contributing to the overall sustainability of the solar installation.

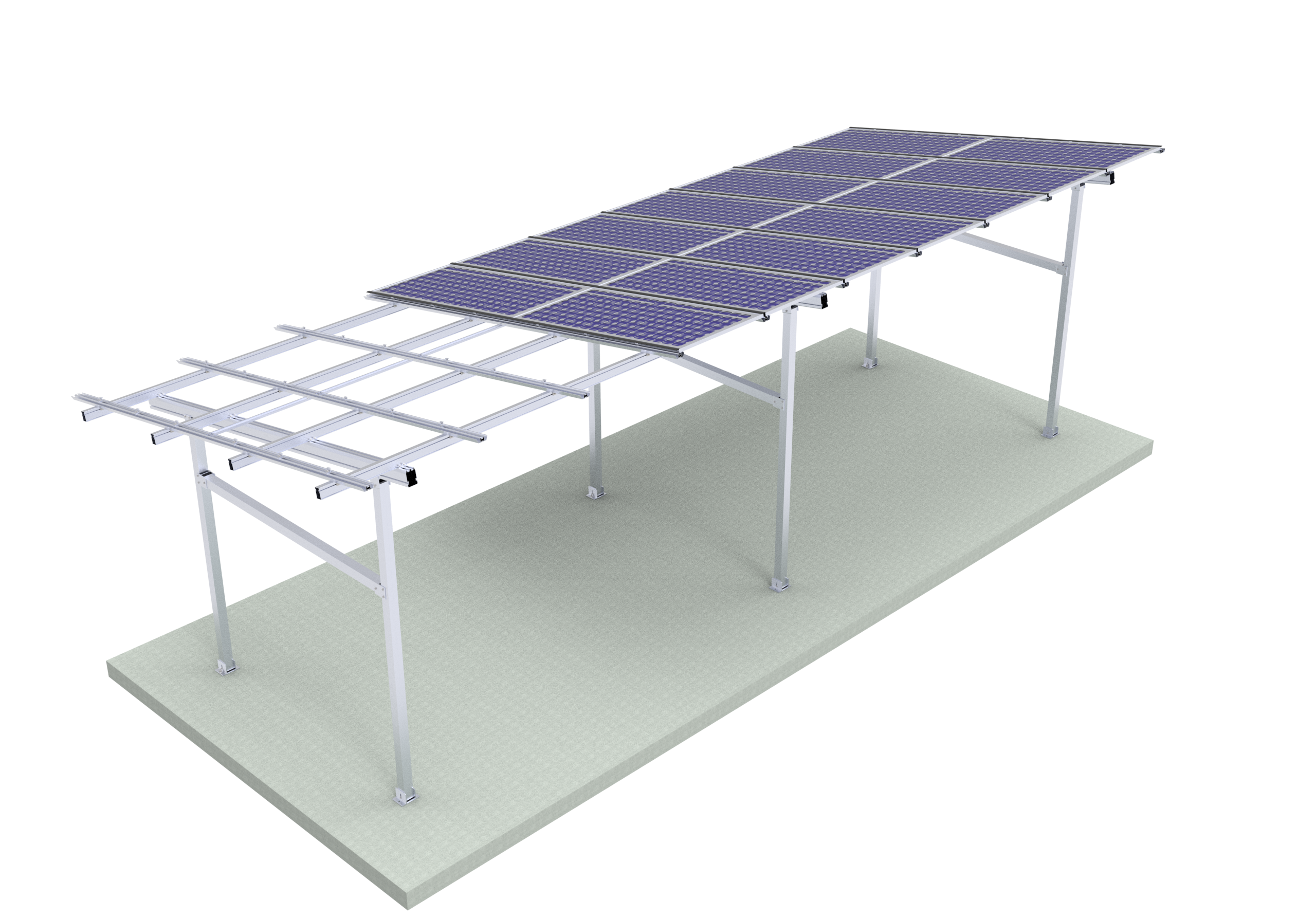

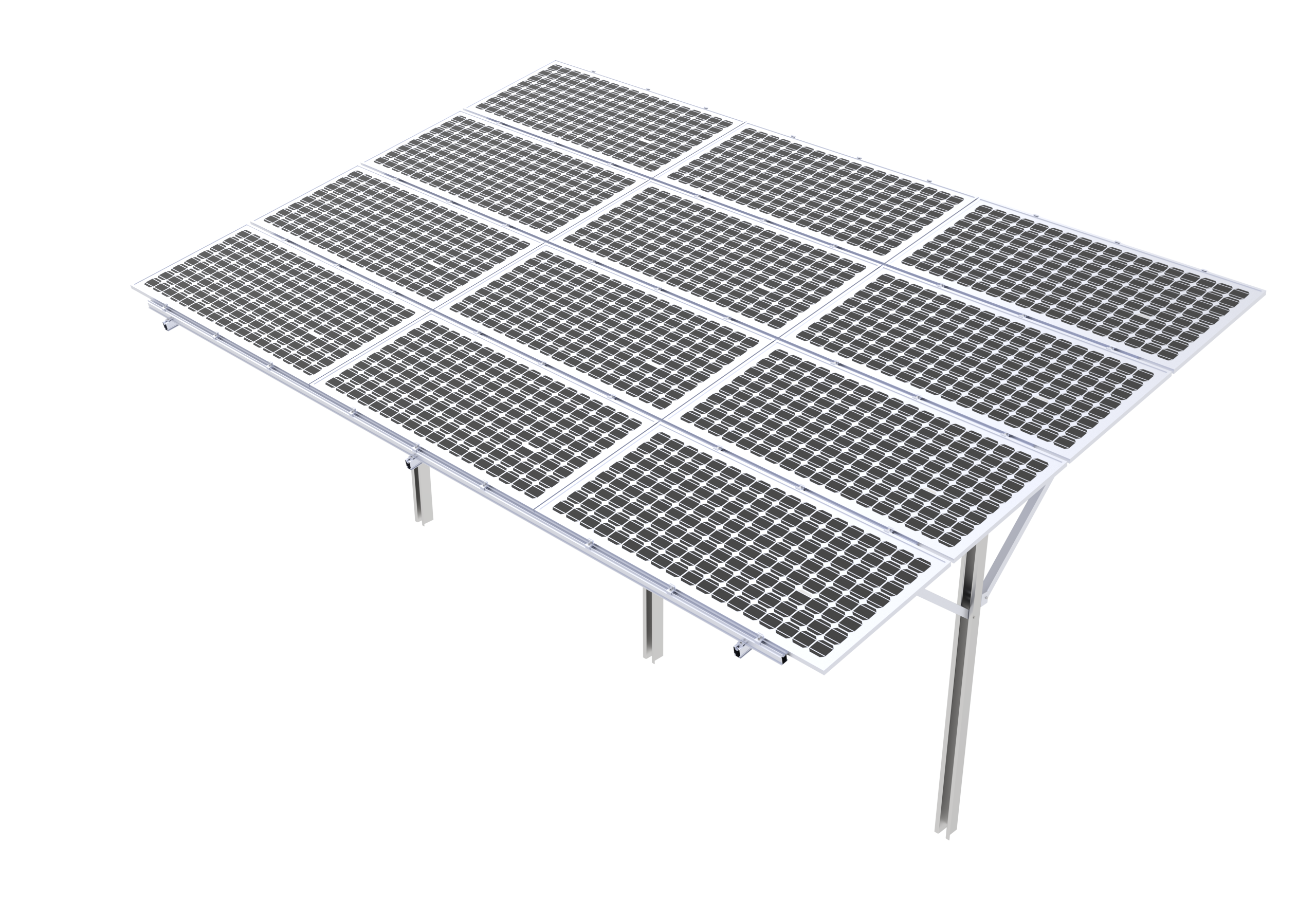

Primary Types of Aluminum Mounting Structures for Metal Roofs

The mounting method is determined by the profile of the metal roof.

1. For Standing Seam Metal Roofs (The Premium Solution)

This is the most common and preferred scenario for new commercial and high-end residential buildings. Standing seam roofs have vertical seams that are mechanically seamed together, forming a strong, continuous ridge.

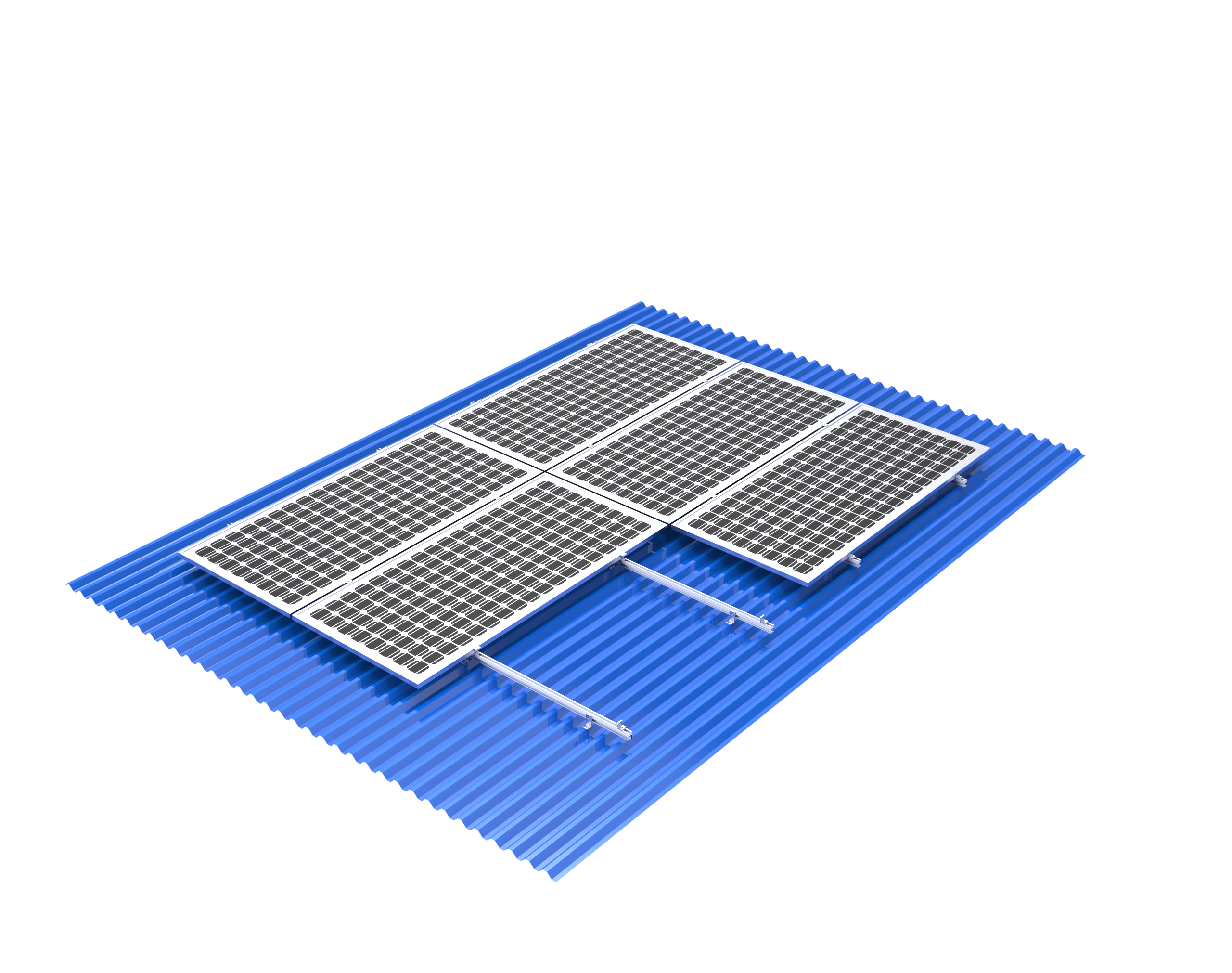

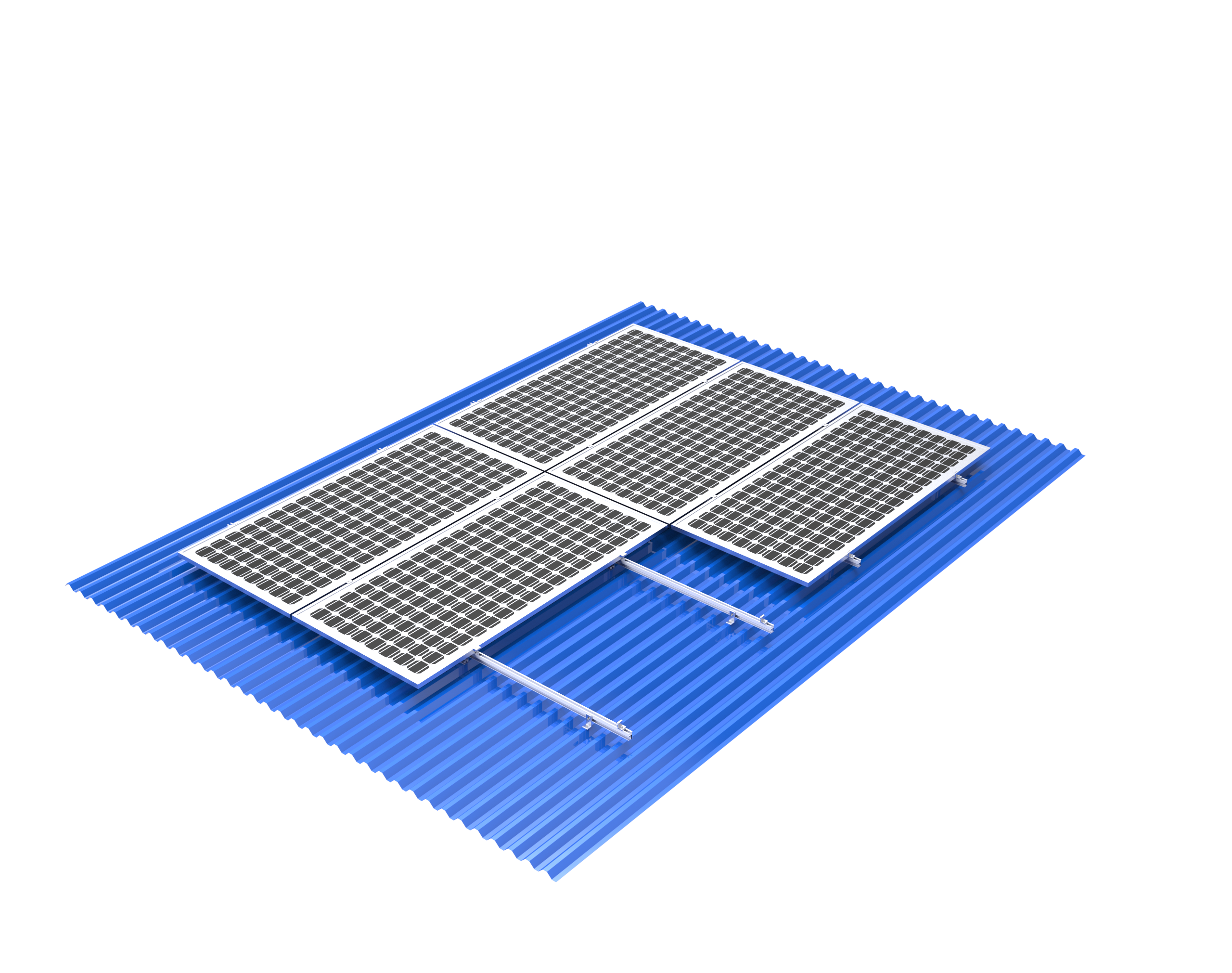

2. For Through-Fastened (Corrugated) Metal Roofs

These roofs have exposed fasteners (screws) that hold the panels to the underlying structure. They are common on older commercial, industrial, and agricultural buildings.

Butyl Tape: A thick sealant tape is placed under the base of the foot.

Key Design and Engineering Considerations for Aluminum Structures

1.Wind Uplift Calculations: This is the most critical engineering factor. The mounting system must be certified to withstand the specific wind speeds of the location. Engineers calculate the loads and determine the required spacing between clamps or feet to prevent the array from being lifted off the roof. Systems are tested to standards like ASTM E1516.

2.Thermal Expansion: Both the metal roof and the aluminum racking expand and contract with temperature changes. The design must accommodate this movement. On standing seam systems, the clamps often allow for slight lateral movement along the seam. Rail splices are also designed to be flexible.

3.Electrical Grounding: The entire aluminum structure must be properly bonded and grounded to the building's grounding electrode system. This is a safety requirement to protect against electrical faults and lightning strikes. Specialized grounding lugs that bite through the rail's anodized layer are typically used.

4.Snow Loads: In snowy regions, the system must be designed to hold the weight of accumulated snow without deflecting excessively. This can influence the spacing of rails and supports.

Leading Brands and Product Examples (Aluminum-Specific)

The Future: Trends in Aluminum Metal Roof Mounting

Integrated "Plug-and-Play" Solutions: Manufacturers are creating complete kits tailored to specific metal roof profiles, simplifying the design and procurement process for installers.

In summary, aluminum solar mount structures are the engineered backbone that makes metal roofs one of the best possible platforms for solar energy. The combination of aluminum's material properties with penetration-free mounting techniques creates a durable, reliable, and safe system perfectly matched to the long lifespan of both the solar panels and the metal roof itself.