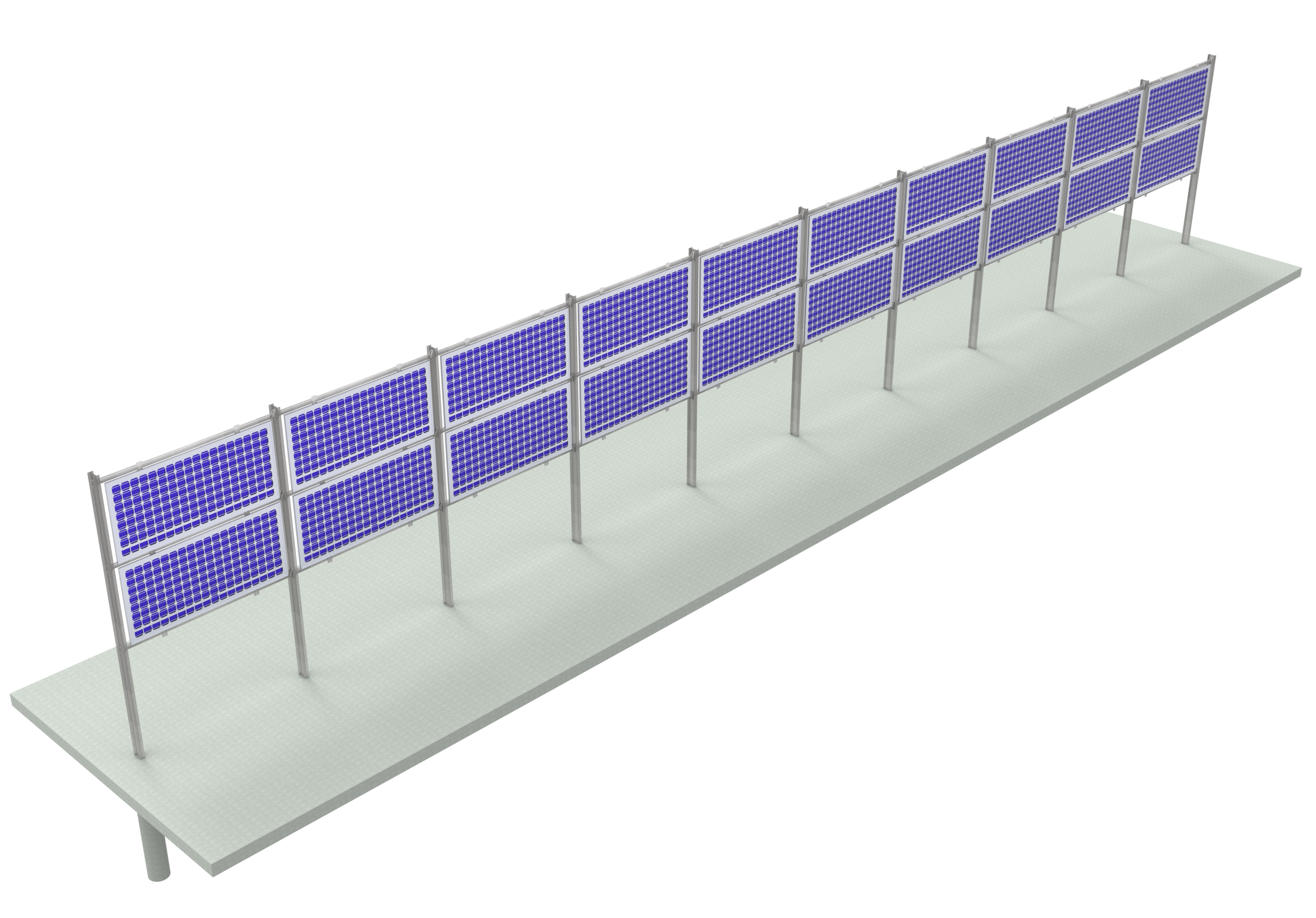

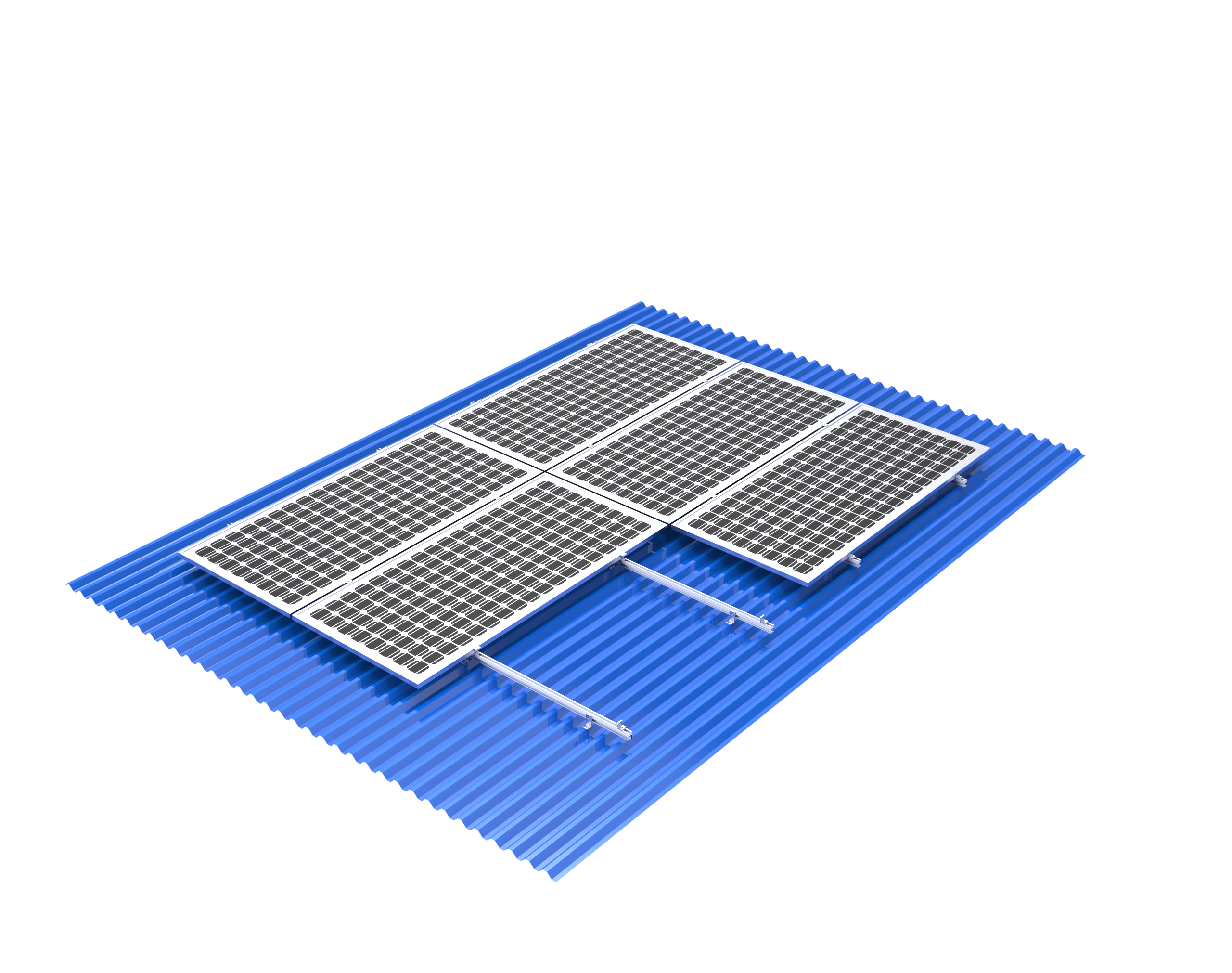

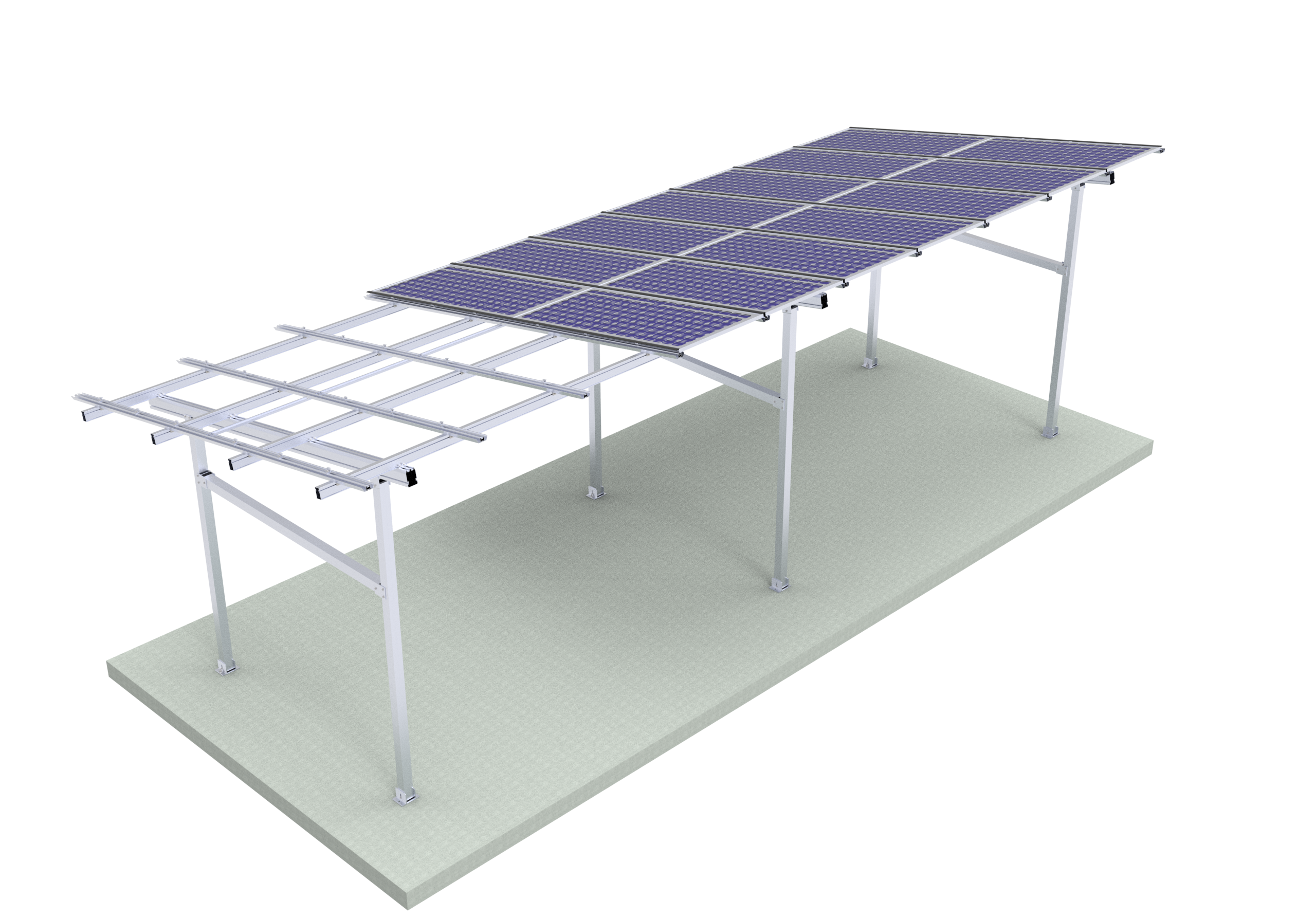

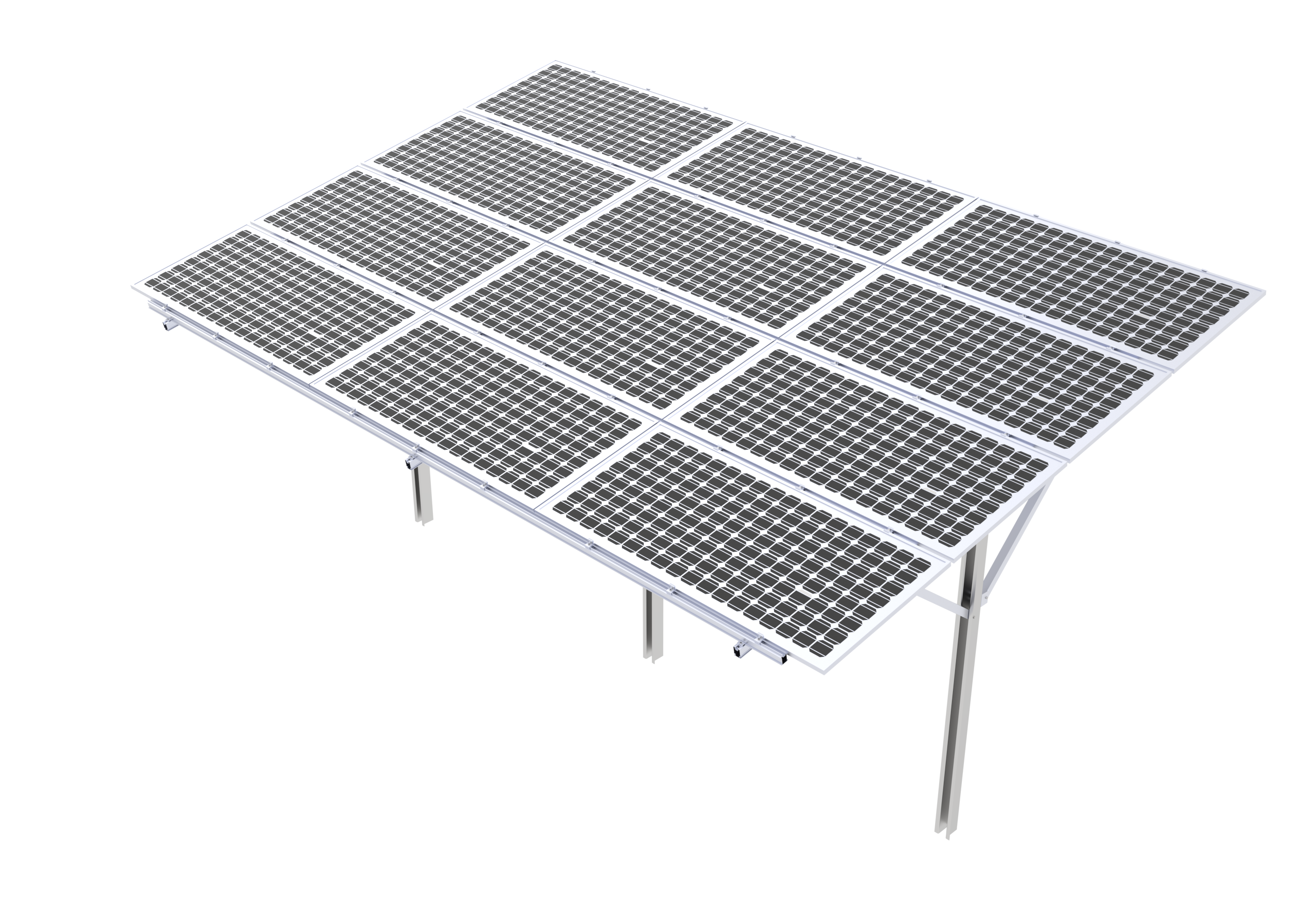

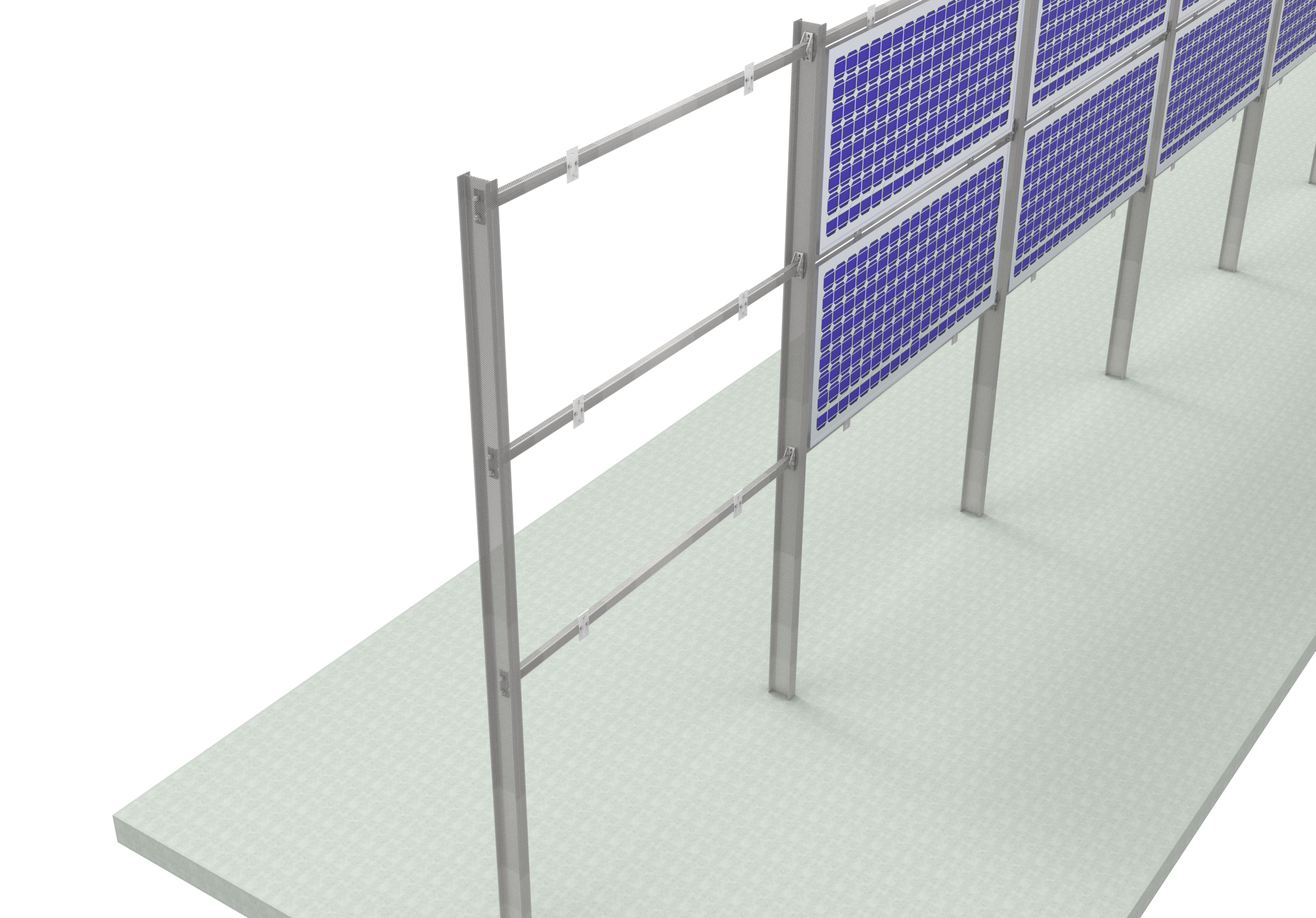

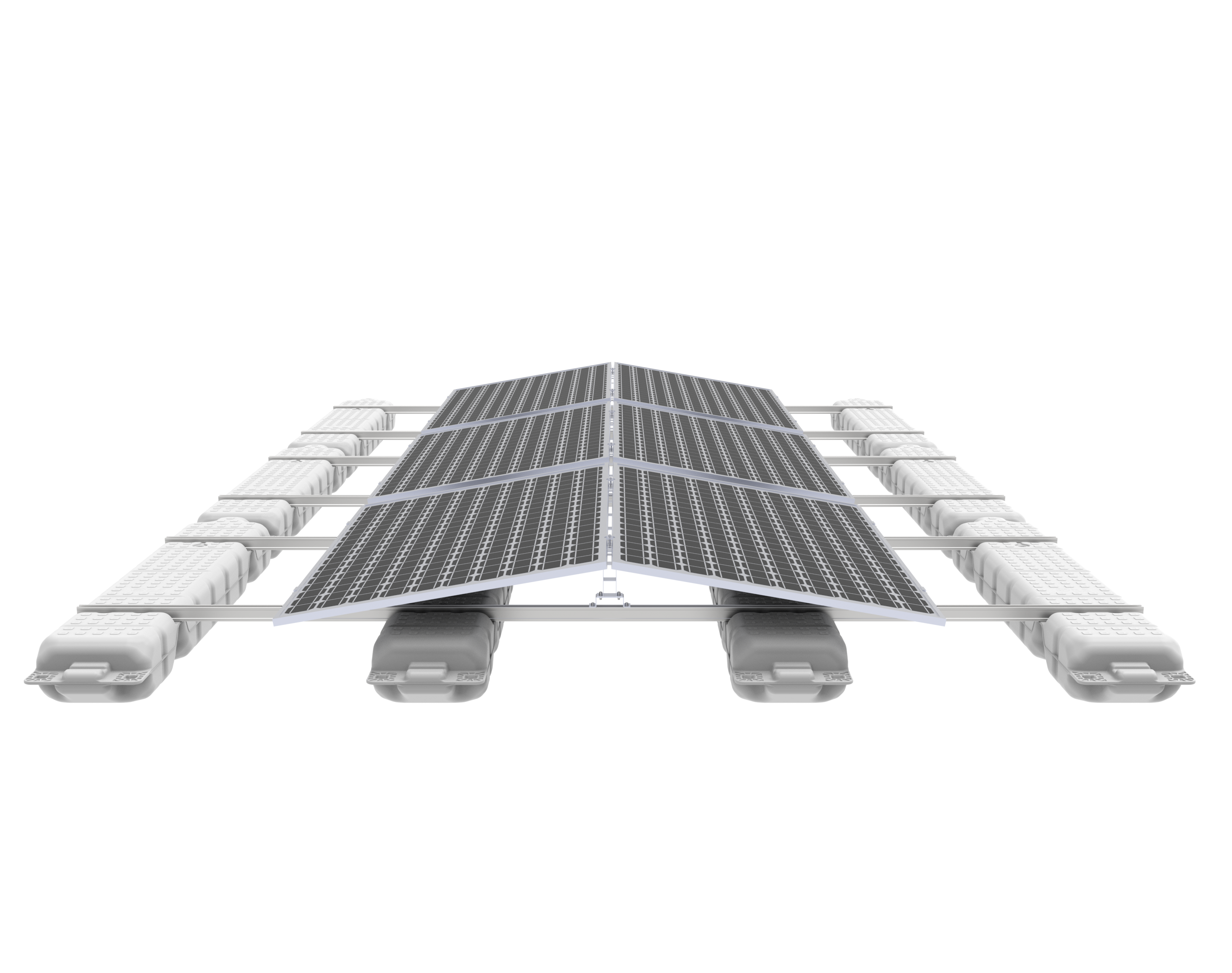

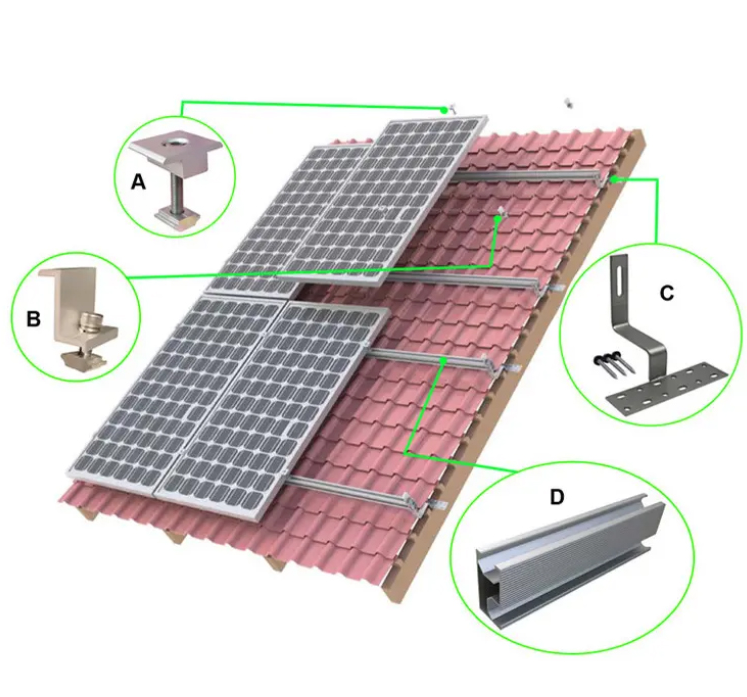

Single pole aluminum solar mounting racks are a specialized type of solar support structure designed for small- to medium-scale PV installations, offering a balance between strength, durability, and efficient land usage. Unlike traditional multi-pole or ground-mounted systems that require several supporting legs, single pole systems rely on one central column to hold the solar array, making them highly space-saving and visually neat. Here’s a more detailed overview:

2025-08-28

More